Your brand’s reputation depends on your suppliers. A single counterfeit or low-quality product can destroy trust built over years. In 2024, businesses lost over $42 billion globally to unreliable suppliers, with 60% reporting supplier-related issues. The counterfeit market, worth $2 trillion annually, not only damages businesses but also costs 2.5 million jobs worldwide.

To protect your brand, supplier vetting is critical. Here's how you can safeguard your supply chain:

- Define clear requirements: Specify product standards, certifications (e.g., ISO, FDA), and intellectual property protections.

- Verify credentials: Check business licenses, certifications, and use third-party audits to confirm legitimacy.

- Conduct background checks: Analyze performance history, credit reports, and transaction data.

- Test product samples: Ensure initial and ongoing quality through inspections and trial production runs.

- Monitor continuously: Regular audits, scorecards, and customer feedback help maintain supplier reliability.

Skipping these steps can lead to financial losses, legal risks, and reputational damage. Investing 50–80 hours over 4–6 weeks in vetting can save up to 64% on costs while ensuring quality.

Key tools and strategies:

- Use platforms like ForthSource or ImportGenius for supplier data and trust scores.

- Implement tracking systems (e.g., RFID, blockchain) to secure shipments.

- Regularly review supplier performance with scorecards.

Supplier vetting isn’t a one-time task - it’s a process that protects your brand and builds stronger partnerships. Start now to avoid costly mistakes later.

How to Vet China Suppliers for US & EU Compliance CE, FCC, FDA

Why Counterfeit Suppliers Are Dangerous and Why Vetting Is Necessary

Counterfeit suppliers exploit weaknesses in vetting processes to infiltrate supply chains, causing financial losses, damaging reputations, and exposing businesses to serious legal risks. Let’s break down these dangers and why thorough supplier vetting is so important.

Financial and Reputation Damage from Counterfeit Products

Sending a 30% deposit to a fraudulent supplier can lead to immediate financial loss. On top of that, businesses face additional expenses from product returns, recalls, and the fallout of losing customer trust. Customs authorities may also seize non-compliant shipments, leaving you with no product and no way to recover your investment.

The damage doesn’t stop there. When customers receive counterfeit or poor-quality products, your brand takes the hit. Expect negative reviews, public backlash on social media, and long-term customer loss.

"Counterfeit products erode that confidence, and more importantly, they put consumers at risk", said Thomas Barden, Senior Vice President at L'Oréal USA.

How Counterfeit Products Get Into Your Supply Chain

Counterfeiters employ clever tactics to infiltrate your supply chain. For instance, trading companies often pose as manufacturers, using fake factory photos and bogus certifications. They may then outsource production to unverified third parties, leading to substandard or entirely wrong products being delivered - or no products at all.

Another common trick involves presenting a flawless "golden sample" to win your contract, only to substitute cheaper, inferior materials during mass production. Fraudulent suppliers may also insist on off-platform payments, stripping away financial protections.

Intellectual property theft is another major risk. Suppliers with access to your exclusive designs can leak them to competitors or create unauthorized copies. The physical and cultural distance between you and the supplier often makes on-site verification difficult, giving these bad actors an edge.

These practices not only compromise the quality of your products but also leave you exposed to legal and financial consequences.

Legal Consequences of Counterfeit Products

Selling counterfeit goods - even unknowingly - can lead to severe legal penalties. Trademark or copyright infringement lawsuits can result in huge financial damages. For example, in May 2024, the U.S. District Court for the District of New Jersey sentenced Onur Aksoy to over six years in prison for selling counterfeit Cisco products worth millions, following a joint investigation by Amazon and Cisco. In another case, counterfeiters were ordered to pay more than $7.5 million in damages for selling fake DVDs.

eCommerce platforms like Amazon are cracking down hard. Since 2020, Amazon’s Counterfeit Crimes Unit has pursued over 24,000 counterfeiters through lawsuits and criminal referrals. In 2024 alone, the platform identified and destroyed more than 15 million counterfeit items globally. Platforms can also freeze your funds, shut down your seller account, and require you to refund customers if counterfeit goods are traced back to you.

Customs authorities add another layer of risk by seizing counterfeit shipments, which can result in total inventory loss and fines. On top of all this, counterfeit components that cause property damage, injuries, or deaths can lead to product liability claims, exposing your business to unlimited financial and criminal penalties.

"This ruling sends a clear message that counterfeiting operations, regardless of their sophistication or global reach, will face serious consequences", said Kebharu Smith, Director of Amazon's Counterfeit Crimes Unit.

Understanding these risks is the first step toward implementing a rigorous supplier verification process that protects your business from these dangers.

How to Vet Suppliers for Brand Protection

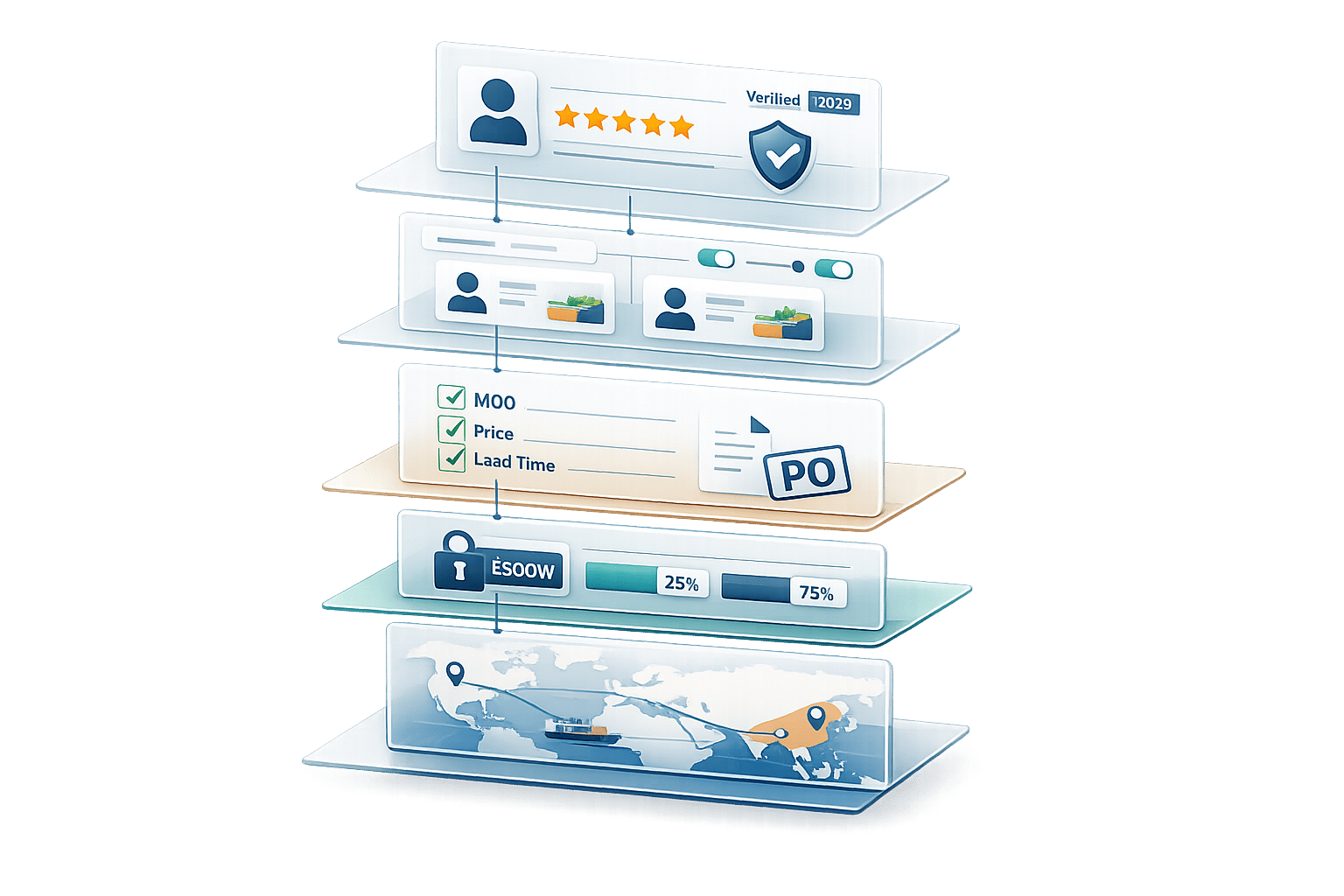

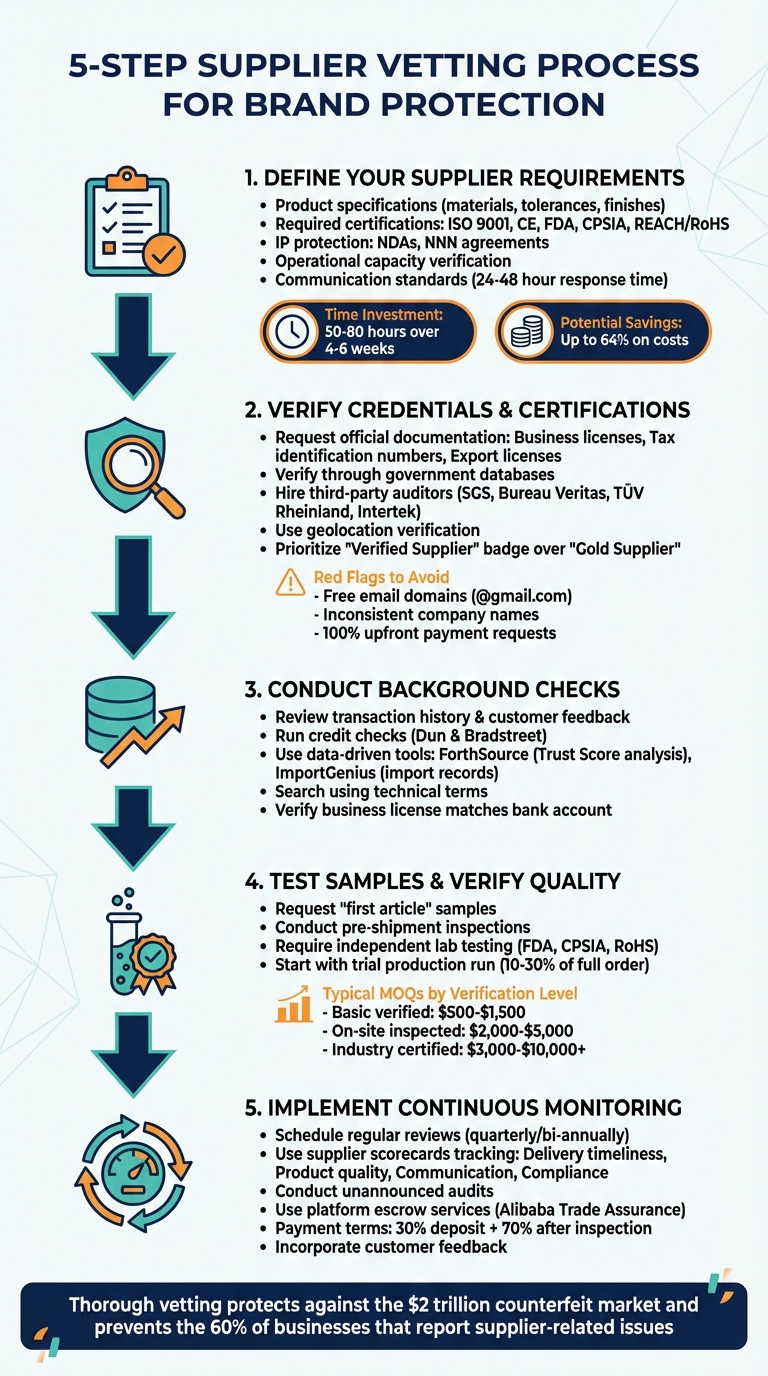

5-Step Supplier Vetting Process for Brand Protection

Now that you're aware of the risks, it's time to establish a thorough vetting process. The goal? Weed out fraudulent suppliers before they infiltrate your supply chain. Here's a step-by-step guide to get you started.

Step 1: Define Your Supplier Requirements

Start by clearly outlining your needs in a detailed specification. This should cover product materials, tolerances, finishes, functional requirements, and packaging standards. A well-defined spec helps prevent unauthorized substitutions or lapses in quality during production.

Identify the regulatory compliance and certifications your products must meet. Depending on your industry, this could include ISO 9001 for quality management, CE marking for European markets, FDA approval for U.S. products, CPSIA for children's items, or REACH/RoHS for chemical safety. Specify exactly which certifications are relevant to your product category.

Protect your intellectual property by requiring Non-Disclosure Agreements (NDAs) or NNN agreements (Non-Disclosure, Non-Use, Non-Circumvention). Contracts should explicitly state that you own all molds, tools, and designs.

Don’t forget about operational capacity. Confirm that suppliers can handle your production volume and scale if needed. Ask about their raw material sources and contingency plans in case of supply disruptions. Also, set clear communication standards - expect timely responses (within 24–48 hours) and transparency about production risks.

While this vetting process may take 50 to 80 hours over four to six weeks, the payoff is worth it. Businesses that work with thoroughly vetted overseas suppliers can save up to 64% on costs.

Step 2: Verify Credentials and Certifications

Request official documentation such as business licenses, tax identification numbers, export licenses, and ownership details. However, don’t just accept PDFs at face value - verify the information through official government databases. For instance, use China's National Enterprise Credit Information Publicity System for Chinese suppliers or Vietnam's General Department of Taxation for Vietnamese suppliers.

For certifications, go straight to the source. Counterfeiters often forge ISO 9001, CE, FDA, and RoHS certificates. Verify these directly with the issuing body to ensure they’re current and applicable to your product.

Consider hiring third-party audit firms like SGS, Bureau Veritas, TÜV Rheinland, or Intertek to conduct on-site inspections. These audits confirm production capacity and quality control systems. You can also use geolocation verification to cross-check factory addresses with satellite imagery, ensuring the facility is legitimate and not just an empty lot or residential property.

If you're sourcing through platforms like Alibaba, prioritize suppliers with a "Verified Supplier" badge. This indicates they’ve undergone a third-party audit, which is far more reliable than the "Gold Supplier" status, which only reflects a paid membership.

"A Verified Supplier has undergone an in-depth, on-site audit by a world-leading independent third-party inspection company (like SGS, Bureau Veritas, or TÜV Rheinland)." - Maple Sourcing

Be cautious of red flags: suppliers using free email domains like @gmail.com, inconsistent company names across documents, or those pressuring for 100% upfront payment. Professional audits typically cost a few hundred dollars - an investment that’s small compared to the cost of fraud.

Step 3: Conduct Background Checks and Analyze Data

Dive deeper into each supplier's performance history and reputation. Review transaction data, customer feedback, and trust indicators to assess their reliability.

Run credit checks using tools like Dun & Bradstreet and analyze marketplace transaction data to evaluate financial stability. Suppliers facing financial trouble are more likely to cut corners or abandon production altogether.

For a more comprehensive view, consider data-driven tools like ForthSource (https://forthsource.io). Their proprietary Trust Score evaluates Alibaba suppliers based on pricing, credibility, WeChat data, and legal reports, helping you quickly identify reliable partners.

When researching suppliers, use specific technical terms in your searches. For example, instead of "water bottle", search for "304 stainless steel vacuum flask" to find specialists who truly understand your product’s requirements.

Lastly, double-check that the business license matches the bank account used for payments. Mismatched accounts are a common tactic among fraudsters to avoid traceability.

Step 4: Test Samples and Verify Quality

Never jump into mass production without testing samples. Request "first article" samples that reflect the actual materials and processes the supplier will use.

Be wary of "golden sample" scams, where initial samples are high quality but bulk production falls short. To avoid this, conduct pre-shipment inspections before making final payments.

For sensitive products like cosmetics, electronics, or children’s items, require independent lab testing to verify safety claims. This is especially crucial for products subject to FDA, CPSIA, or RoHS regulations.

Start with a trial production run - 10 to 30% of your full order quantity - before scaling up. This allows you to catch consistency issues early.

Expect suppliers to charge for samples and shipping fees; this is standard practice and helps filter out non-serious buyers. Minimum order quantities (MOQs) often depend on the supplier’s verification level. For example:

- Basic verified suppliers: $500 to $1,500

- On-site inspected factories: $2,000 to $5,000

- Industry-certified suppliers (ISO/FDA): $3,000 to $10,000+

Once you confirm sample quality, enforce ongoing monitoring to maintain supplier integrity.

Step 5: Implement Continuous Monitoring and Audits

Protecting your brand doesn’t stop after the initial vetting. Set up regular review cycles - quarterly or bi-annually - to track supplier performance and address issues early.

Use supplier scorecards to measure performance across key metrics like delivery timeliness, product quality, communication, and compliance with regulations. Include penalties in your agreements for missed deadlines, quality issues, or intellectual property violations.

Conduct inspections at every stage - pre-production, during production, and pre-shipment. Unannounced audits can provide a more accurate picture of daily operations compared to scheduled visits.

Leverage third-party verification firms to conduct random batch inspections and ensure certifications remain valid. For added security, consider digital traceability methods like serialization or identity codes to track products through the supply chain, minimizing the risk of counterfeit goods.

Always use platform-backed escrow services like Alibaba Trade Assurance, which holds payments until delivery and quality are confirmed. Stick to standard payment terms - 30% deposit to start production and 70% upon successful pre-shipment inspection. Avoid paying 100% upfront.

Finally, incorporate customer feedback into your supplier evaluation process. Customers often catch quality or delivery issues that internal teams might overlook, creating a feedback loop that strengthens your supply chain over time.

sbb-itb-633367f

Using Technology and Platforms to Improve Supplier Vetting

Technology takes the guesswork out of supplier vetting by automating the process and uncovering risks that manual checks might miss. The right tools not only save time but also help identify potential red flags more effectively.

Data-Driven Tools for Supplier Discovery

Tools that rely on data can provide a clearer picture of a supplier's reliability. For instance, import record databases like Jungle Scout and ImportGenius use U.S. government import records to verify a supplier’s export history, customer base, and order volumes. Instead of depending solely on a supplier's claims, these platforms let you see if they’ve consistently worked with major retailers like Walmart or Target.

Dave Bryant from EcomCrew shared his experience using these tools: "Their import records confirmed years of collaboration with major North American retailers". This kind of transparency removes uncertainty and helps you avoid falling for trading companies pretending to be manufacturers.

Meanwhile, AI-driven platforms like ForthSource (https://forthsource.io) take vetting to the next level. ForthSource consolidates data from Alibaba suppliers and calculates a Trust Score based on factors like pricing, credibility, WeChat data, and legal reports. By using its real-time insights, you can spot red flags in supplier performance early. Premium features even allow users to calculate real-time landed costs - factoring in shipping, duties, and taxes - so you know the actual price before reaching out to a supplier. These tools complement ongoing monitoring and auditing efforts, making the vetting process more thorough.

For Amazon sellers, automated enforcement tools like Project Zero are game-changers in combating counterfeit products. Powered by machine learning, Project Zero scans entire catalogs for fake listings. In 2024, Amazon reported that its automated protections blocked 99% of suspected counterfeit listings before brands even had to step in.

"Project Zero lets sellers combine Amazon's advanced anti-counterfeiting technology with the ability to search for counterfeit listings and immediately remove them" - Mickey Toogood, Sr. Content Marketing Manager at Amazon

While these tools help verify supplier credibility, ensuring the security of your supply chain also requires monitoring goods in transit.

Tracking and Traceability Systems for Supply Chain Security

Digital vetting is just one part of the equation. To secure your physical supply chain, advanced tracking systems are essential. RFID tags and GPS devices provide real-time location data, helping you detect unauthorized route changes that could signal counterfeit infiltration. If a shipment strays off its planned path, automated alerts notify you immediately.

Tamper-evident seals and blockchain logs add another layer of protection. Tamper-evident packaging shows visible signs if a product has been opened or altered during transit. On the other hand, blockchain technology creates a permanent, unchangeable record of a product’s journey. Every step - from sourcing raw materials to final delivery - is logged on a decentralized ledger, making it nearly impossible for counterfeiters to insert fake goods into your supply chain undetected.

In industries like semiconductors, where counterfeiting costs U.S. companies over $7.5 billion annually, AI inspection tools play a critical role. These tools can quickly spot discrepancies, helping to reduce the risks associated with counterfeit components. Between 2021 and 2022, reported counterfeit and nonconforming parts rose by 35%, despite flat global sales.

"Through robust supplier qualification and risk mitigation practices, procurement professionals can maintain stringent supplier controls to ensure high levels of product quality" - Krishna Ganason, Director of Engineering at Fusion Worldwide

Building Long-Term Supplier Relationships for Brand Protection

Protecting your brand goes beyond just screening suppliers at the start. It’s about fostering long-term partnerships that ensure ongoing adherence to your quality standards. When you treat suppliers as strategic allies, you create an environment where transparency thrives, especially regarding production capacity and supply chain risks. This collaborative approach not only strengthens your brand but also helps you navigate market fluctuations with greater confidence. Shifting from one-time vetting to sustained partnerships is a key step in safeguarding your supply chain.

Building Mutual Accountability and Trust

The foundation of any strong supplier relationship is built on mutual respect and clear communication. Start by drafting detailed manufacturing agreements that outline everything from quality expectations to intellectual property protections and penalties for non-compliance. These agreements set the tone, ensuring both parties know what’s expected from the very beginning.

Regular in-person meetings and factory visits can go a long way in building trust. These interactions create personal connections and provide opportunities to address potential issues before they escalate. It’s also important to ask suppliers about their own supply chain vulnerabilities. Understanding these risks fosters transparency and reduces the chances of unexpected problems, like defects that could harm your brand. With these elements in place, you can establish a solid foundation for tracking performance objectively.

Creating Compliance and Performance Scorecards

Scorecards transform subjective opinions into actionable data. Once you’ve set high standards during the vetting process, use scorecards to monitor key metrics such as:

- Quality: Defect rates and rework percentages

- Delivery: On-time shipping and adherence to lead times

- Communication: Responsiveness and transparency

- Compliance: Valid certifications and audit history

- Cost: Price stability and payment terms

These scorecards should be updated after every major transaction or audit, providing a real-time snapshot of supplier performance. Monthly reviews are a great way to share summary results with suppliers, while quarterly reviews can feed this data into strategic dashboards. This consistent feedback loop helps suppliers understand their strengths and areas for improvement.

"Keep a supplier score-card for future references... include these metrics in our monthly supplier reviews and share summary score-cards with our brand clients." - Sourcify

Using scorecard data, you can categorize suppliers into tiers: "keep", "re-negotiate", or "remove." Only increase order volumes when a supplier demonstrates consistent performance over multiple review cycles. This method rewards reliable partners while protecting your brand from risks like counterfeit goods or unreliable deliveries.

Conclusion

Supplier vetting isn’t just a one-time task - it’s an ongoing process that shields your business from financial setbacks, intellectual property risks, and damage to your reputation. Businesses that take the time to thoroughly vet overseas suppliers can save as much as 64% on costs while still maintaining quality and reliability.

Trying to cut corners often backfires. Quality issues, delays, and compliance problems can quickly eat away at any initial savings. As James Kennemer wisely points out, "The cheapest quote rarely delivers the lowest total cost".

To build a strong foundation, focus on the essentials: define your requirements, verify supplier credentials, conduct audits, test product samples, and implement scorecard monitoring. Avoid paying 100% upfront to new suppliers, and always insist on independent quality control inspections. These steps are critical for creating a supply chain that’s resistant to counterfeit products and other risks.

Technology can take these efforts to the next level by simplifying supplier discovery and verification. Platforms like ForthSource bring together aggregated data and trust scores based on verified information, pricing, and credibility indicators. Combined with physical security measures and continuous monitoring, these tools transform supplier vetting from a time-intensive chore into a strategic advantage.

FAQs

What are the essential steps to vet suppliers and protect your brand?

A solid supplier vetting process is crucial for building partnerships with dependable and reputable suppliers. Start by laying out your requirements in detail - this includes specifying product features, order volumes, lead times, and prioritizing factors like cost, quality, or safeguarding intellectual property. Having this clarity upfront makes it easier to pinpoint suppliers that align with your goals.

The next step is an initial screening to filter potential candidates. Key considerations include production capabilities, relevant certifications, and references. Once you’ve narrowed the list, dive deeper into due diligence. This means verifying certifications, checking legal compliance, reviewing financial health, and, if feasible, conducting factory audits. For international suppliers, pay special attention to risks like counterfeit products, intellectual property theft, and disruptions in the supply chain.

Leveraging tools like ForthSource can make this process smoother. These platforms provide real-time data, assign credibility scores, and help you identify trustworthy suppliers more efficiently. By combining clear expectations, thorough vetting, and continuous monitoring, you can safeguard your brand and maintain a robust supply chain.

What are the risks of counterfeit products for my brand?

Counterfeit products pose a serious threat to your brand. They can confuse customers, weaken trust, and tarnish your reputation. Beyond that, these fake goods often violate trademarks, putting your business at risk of legal troubles, including lawsuits under U.S. trademark laws.

The impact doesn't stop there - counterfeit items can also lead to enforcement actions and hefty financial penalties. This is why it's so important to carefully vet your suppliers. Partnering with trustworthy suppliers helps safeguard your brand, keep your customers loyal, and steer clear of expensive legal headaches.

What technologies can help improve supplier vetting and secure the supply chain?

Technologies like AI-powered tools, cybersecurity measures, and real-time supply chain monitoring platforms are reshaping how businesses approach supplier vetting and supply chain security. AI-driven systems, for instance, can sift through massive datasets - like legal records and credibility scores - to pinpoint reliable suppliers and flag potential risks.

Cybersecurity also plays a key role in shielding supply chains from threats such as counterfeit goods or malicious activities. Many companies now implement advanced frameworks to protect their operations. On top of that, tools designed to analyze import records and verify supplier histories allow brands to confirm authenticity and track shipments, which helps reduce risks and boosts transparency.

By tapping into these technologies, businesses can make better sourcing decisions, lower product-related risks, and ensure their supply chains remain secure and dependable.