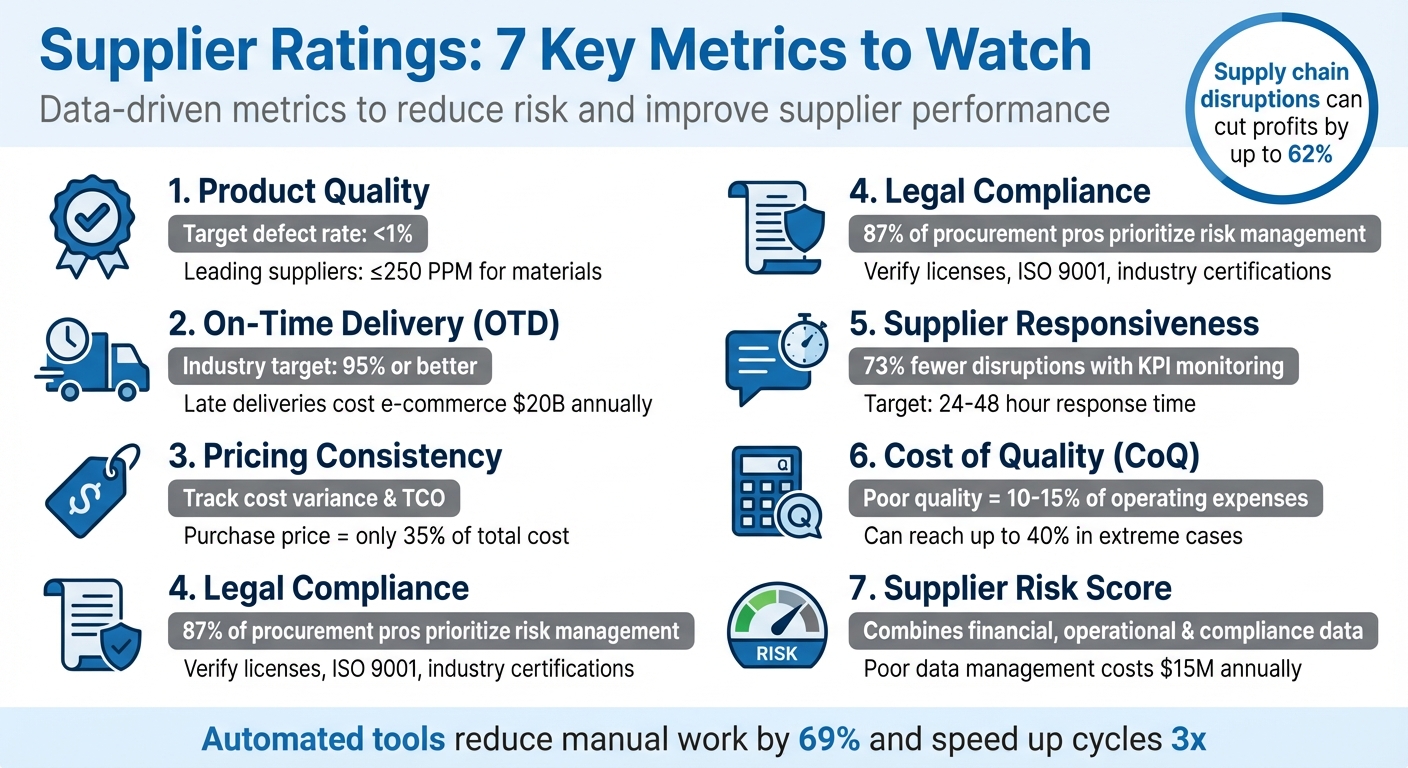

When choosing suppliers, relying on outdated methods like spreadsheets or gut instincts can lead to big problems - think supply chain disruptions that cut profits by up to 62% or poor data management costing $15 million annually. But tracking key metrics can help you avoid these risks and improve supplier performance. Here's what to focus on:

- Product Quality: Defect rates, return frequency, and compliance with standards like ISO 9001. Poor quality can lead to recalls and damage your brand.

- On-Time Delivery (OTD): Measure delivery reliability. Late shipments cost industries billions and hurt customer trust.

- Pricing Consistency: Monitor cost variance and Total Cost of Ownership (TCO) to avoid unexpected expenses.

- Legal Compliance: Verify licenses, certifications, and audit histories to reduce risk.

- Supplier Responsiveness: Track how quickly suppliers handle inquiries and resolve issues to minimize disruptions.

- Cost of Quality (CoQ): Account for prevention and failure costs to see the true financial impact of poor quality.

- Supplier Risk Score: Combine metrics like financial stability, compliance, and delivery performance to predict future risks.

Using automated tools like ForthSource simplifies this process, providing real-time data and scores to make smarter decisions. Managing these metrics reduces risks, cuts costs, and improves supplier relationships.

7 Key Supplier Rating Metrics to Track for Better Procurement Decisions

5 Best Metrics to Measure your Suppliers Performance

1. Product Quality

When evaluating suppliers, product quality is a top priority. It’s assessed through factors like defect rates, compliance with specifications, and adherence to quality control standards. For instance, a defect rate under 1% generally reflects strong quality control, while rates exceeding 15% point to deeper systemic problems that demand immediate attention. These numbers directly affect customer satisfaction, return rates, and your brand’s reputation.

The consequences of ignoring quality metrics can be catastrophic. Take Samsung’s 2016 battery crisis as an example: batteries from two suppliers failed to meet critical standards, leading to fires and a global recall. This disaster cost Samsung billions of dollars and dealt a severe blow to its reputation. Another example is Mattel’s 2007 recall of 18 million toys due to lead-contaminated paint and dangerous magnets. The fallout included $30 million in direct costs, a sharp decline in share value, and a complete overhaul of their supplier auditing processes.

"When it comes to quality, it should be a matter of either zero or 100% or only black or white and no grey. What I mean by this is that there is no such thing as 'acceptable poor quality' products."

– Akinori Hyodo, Former Factory Manager, Toyota

These incidents highlight why rigorous quality standards are non-negotiable.

Another critical measure is return frequency. High return rates due to defective or damaged products not only waste resources but also erode customer trust and inflate operational costs. Leading suppliers aim for exceptional performance, such as maintaining ≤ 250 PPM (parts per million) for direct materials and ≤ 50 PPM for finished goods. To ensure consistent quality management, it’s crucial to establish clear benchmarks (like a 1–5 rating scale), conduct regular operational audits, and verify certifications such as ISO 9001.

Tools like ForthSource make supplier evaluation more efficient by providing real-time insights into supplier credibility and quality. This proactive approach helps identify potential quality issues early, preventing costly recalls or customer dissatisfaction.

2. On-Time Delivery

On-time delivery (OTD) tracks the percentage of orders that arrive on or before the promised date. It’s calculated using the formula: (on-time deliveries ÷ total deliveries) × 100. This metric is a key indicator of reliability - when suppliers miss deadlines, it damages trust and often highlights deeper issues in procurement or production processes. Beyond trust, the financial impact of delayed deliveries is hard to ignore.

Late shipments cost the e-commerce industry an estimated $20 billion annually. Retailers like Walmart have responded with strict measures, including a 3% penalty for missed delivery windows. And the stakes are even higher with customers - 86% of shoppers won’t return after a single bad delivery experience. This shift in consumer expectations has set a higher bar for B2B performance, where achieving a 90% OTD rate is no longer sufficient. Leading companies now aim for 95% or better.

Consistency in lead times is just as critical as hitting OTD targets. When deliveries are unpredictable, businesses often overcompensate by holding excess safety stock, tying up valuable capital. Companies with disconnected systems average a 78% OTD rate, but those using integrated systems can reach 93% within six to eight months. The challenge is growing, with 64% of manufacturers in 2024 reporting that maintaining reliable OTD is harder than it was five years ago.

To improve delivery performance, it’s essential to establish clear Service Level Agreements (SLAs) that include financial penalties for missed deadlines and rewards for exceeding targets. Regularly comparing actual delivery times against promised lead times can help identify bottlenecks. Critical suppliers should be reviewed monthly or quarterly, while standard suppliers can be evaluated annually. Automated purchase order management systems are another effective tool, reducing manual errors and providing real-time shipment updates.

Platforms like ForthSource take this a step further by offering real-time data on supplier performance. By identifying potential delivery risks early, these tools help businesses make smarter sourcing decisions and maintain lean inventory levels, keeping operations efficient and competitive.

3. Pricing Consistency

Pricing consistency measures how reliably a supplier maintains steady costs over time. A key metric for this is cost variance - the gap between the expected cost and the actual amount paid. When suppliers frequently adjust prices or tack on unexpected fees, it can throw budgets off track and put entire projects in jeopardy.

Unexpected fees can inflate the real cost of doing business. This is why it's essential to monitor the Total Cost of Ownership (TCO), which includes not just the purchase price but also expenses like shipping, storage, handling, and administrative overhead. Surprisingly, the initial purchase often accounts for only about 35% of the total cost.

Keeping an eye on stable pricing also enhances negotiation power. Reliable pricing data allows teams to spot trends in cost fluctuations, giving them the upper hand in securing better terms and identifying savings opportunities. For instance, companies using supplier scorecards to track price variance have reported an average of 12% savings through improved sourcing strategies. Setting clear benchmarks - such as a maximum allowable variance percentage - and reviewing these metrics monthly for key suppliers ensures better control over your Cost of Goods Sold (COGS). This approach transforms sourcing into a data-driven process.

Tools like ForthSource make it easier to track pricing patterns by aggregating real-time data and using scoring systems. This transparency helps businesses identify suppliers with stable pricing while steering clear of those with unpredictable cost structures. By analyzing the complete picture - including indirect costs and pricing trends - you can safeguard profit margins and make smarter sourcing decisions for the long run.

"The lowest price is very often not the best buy. When assessing cost-effectiveness, buyers must evaluate cost vs. value." - Netstock

4. Legal Compliance

Ensuring legal compliance is crucial for protecting your business from supply chain hiccups and potential liability issues. Here's why it matters: supply chain disruptions can wipe out 62% of a company's profits, and a staggering 87% of procurement professionals now rank managing supplier risk as their top priority. By establishing a solid compliance framework, you can create a strong foundation for effective vendor management across your supply chain.

Start by covering the essentials. Check that your suppliers have valid business registrations, appropriate business licenses, and export licenses. Next, verify quality certifications like ISO 9001, ensuring they specifically apply to the products or facilities you’re dealing with.

Compliance requirements often vary by industry. For example:

- Healthcare suppliers must meet HIPAA and FDA standards.

- Financial sector vendors need to comply with Sarbanes-Oxley and Anti-Money Laundering regulations.

- Construction suppliers are required to adhere to OSHA standards.

Failing to verify these certifications could lead to serious legal and operational risks for your business.

It’s also smart to go beyond certificates. Review a supplier's audit history and look for any major non-conformities in their most recent reports. Including "right to audit" clauses in your contracts can give you the flexibility to verify compliance whenever necessary. This is especially important as 70% of companies report that supply chain risks have increased significantly in the past three years.

For added efficiency, platforms like ForthSource make legal validation easier by consolidating verified business licenses and compliance data directly from Alibaba suppliers. Their Trust Score system evaluates legal documentation, helping you weed out unverified vendors early in the process. This streamlined approach turns what used to be a time-consuming task into a quick, reliable way to protect your brand and bottom line.

sbb-itb-633367f

5. Supplier Responsiveness

Supplier responsiveness plays a key role in minimizing supply chain risks. When suppliers delay responses or fail to address order changes, your operations can face serious disruptions. Responsiveness reflects how quickly suppliers answer inquiries, confirm orders, and resolve issues. In a fast-paced environment where orders often change, a supplier's ability to react swiftly becomes essential for keeping things on track.

Here’s an eye-opener: 73% of organizations that monitor supplier performance through KPIs report fewer supply chain disruptions. These companies have seen a 20% improvement in lead times and a 15% drop in procurement costs by actively managing supplier performance.

"When suppliers are slow to respond to changes (or don't respond at all), you've introduced risk into your supply chain." – SourceDay

To evaluate responsiveness effectively, consider setting clear benchmarks. For instance, require suppliers to acknowledge orders within 48 hours and respond to inquiries within 24 to 48 hours. Additionally, track how quickly they resolve issues and whether they proactively report potential problems. Suppliers who inform you of issues before they escalate bring real value, as this proactive approach enhances reliability across the board.

ForthSource simplifies this process by offering real-time insights into supplier communication and responsiveness. By aggregating these metrics, ForthSource helps you pinpoint the most efficient vendors. This transparency transforms responsiveness into a measurable strength that protects and optimizes your operations.

6. Cost of Quality

The sticker price only tells part of the story. The Cost of Quality (CoQ) takes a deeper dive, accounting for both prevention costs (like inspections and training) and failure costs (such as rework, scrapped materials, warranty claims, and returns).

For many successful companies, the cost of poor quality can eat up 10–15% of their operating expenses. In extreme situations, these quality-related costs can skyrocket to as much as 40% of total business expenses. When you factor in defects, returns, and rework, that seemingly "cheap" supplier might end up draining your budget far more than expected.

"If we buy on price, whilst the initial expense to our business may be favorable, over a period of time it is likely to cost more than if we evaluated the costs initially." – Katie Jarvis-Groves, The Oxford College of Procurement and Supply

Understanding these hidden costs makes evaluating CoQ an essential step in supplier selection. By tracking CoQ, you shift your focus from just the upfront cost to the Total Cost of Ownership (TCO) - a more complete financial picture that includes freight, duties, maintenance, and quality-related failures. For example, a supplier offering low prices but delivering high defect rates will often cost more in the long run compared to a higher-priced vendor with consistent quality.

Leverage tools like your ERP system to automatically track key metrics, such as write-offs, rework service orders, and inspection results. This ensures you're relying on objective, real-time data to make informed decisions.

7. Supplier Risk Score

A Supplier Risk Score takes the guesswork out of evaluating supplier reliability by combining key metrics into a single, predictive measure. While individual metrics focus on past performance, this consolidated score looks ahead, offering insights into potential risks. It merges factors like financial stability, incident history, operational reliability, and compliance into one number, providing a clear picture of whether a supplier is likely to remain dependable - or become a liability. This approach not only reflects past performance but also highlights emerging risks that might be missed when metrics are viewed in isolation.

The stakes are high. Supply chain disruptions can slash 62% of a company’s profits, and poor supplier data management costs businesses an average of $15 million annually.

A robust Supplier Risk Score incorporates a wide range of data:

- Financial metrics: Credit ratings, debt-to-equity ratios, and Dun & Bradstreet Paydex scores.

- Operational data: Lead-time variability, on-time delivery rates, and disaster-recovery plans.

- Quality indicators: Defect rates (PPM), return frequency, and responsiveness to corrective actions.

- Compliance standards: ISO certifications, ESG assessments, and cybersecurity protocols.

How you interpret and act on these scores is just as important as the score itself. Many procurement teams use a color-coded system for quick decision-making - Green for low risk, Yellow for caution, and Red for high risk. Suppliers with a score below 30 out of 75 often trigger immediate action, such as escalation to a sourcing committee or even a phased exit strategy. For crucial suppliers, conducting reviews monthly or quarterly can help catch issues early, while lower-risk vendors might only need annual check-ins.

"Non-quantifiable or soft data are important in terms of raising flags to dig deeper." – John Evans, Vice President of Procurement, Ingersoll Rand

It’s not just about the numbers. To get a complete picture, include “soft” metrics like management turnover, labor relations, and a supplier’s track record for innovation. These often serve as early warning signs that won’t show up in financial reports.

Tools like ForthSource (https://forthsource.io) make this process easier by automating risk scoring for Alibaba suppliers. By pulling together data on pricing, credibility, WeChat activity, and legal records, ForthSource generates a Trust Score ranging from 0 to 100. This real-time score helps businesses identify reliable partners without relying on intuition alone.

Conclusion

Keeping track of key supplier metrics transforms decision-making from guesswork into a precise, data-driven process. By monitoring factors like product quality, on-time delivery, pricing consistency, legal compliance, responsiveness, cost of quality, and risk scores, you create a solid foundation that not only shields your business from potential disruptions but also enhances supplier relationships. Consistently tracking these metrics boosts operational efficiency and helps minimize risks.

The real challenge lies in managing the sheer volume of data across multiple suppliers. Relying on manual processes can lead to errors and wasted time. It's no surprise that 87% of procurement professionals now prioritize managing supplier risk above all else. Poor supplier data can have a hefty price tag, costing businesses an average of $15 million annually.

Automated platforms offer a powerful solution to this problem. By centralizing data, these tools eliminate manual errors and provide real-time insights into supplier performance. Instead of juggling fragmented data, you get a unified, real-time dashboard that simplifies operations. Teams using modern procurement technology report 69% less manual work and experience cycle times that are three times faster.

Take ForthSource (https://forthsource.io) as an example. This platform brings automation to Alibaba sourcing by consolidating supplier data and assigning a proprietary Trust Score, ranging from 0 to 100. It evaluates pricing trends, credibility indicators, WeChat activity, and legal compliance records, helping DTC brands find trustworthy suppliers without the noise of sponsored listings or unverified claims. With ForthSource, you can objectively compare suppliers, calculate true landed costs (including shipping and duties), and make smarter sourcing decisions based on real-time data.

Incorporating these metrics and automated tools not only reduces risk but also strengthens supplier partnerships and safeguards your profit margins.

FAQs

What are the advantages of using automated tools for supplier ratings?

Automated tools for supplier ratings bring a host of benefits compared to manual methods. They cut down on time-consuming tasks like data entry and reduce the likelihood of human errors. Procurement teams can quickly evaluate suppliers and generate risk scores, streamlining the entire process. Plus, these tools offer real-time updates on key metrics such as on-time delivery, product quality, and pricing consistency, which means faster and more transparent decision-making.

By automating supplier evaluations, businesses gain an objective, data-driven perspective on performance. This approach not only helps in identifying risks and ensuring compliance but also applies consistent evaluation standards. As a result, companies can pinpoint areas that need improvement and address potential issues early, avoiding costly delays or supply chain disruptions.

Platforms like ForthSource take things a step further by incorporating AI-powered analysis, credibility checks, and legal compliance into a single, dynamic scorecard. This allows businesses to find trustworthy suppliers, lower procurement expenses, and build stronger partnerships - all without hidden costs or middlemen getting in the way.

Why is on-time delivery important for building trust and managing costs?

On-time delivery is a critical measure of a supplier's dependability. When products are delivered as scheduled, it not only boosts customer confidence but also encourages repeat purchases and reinforces a brand's standing in the market. On the flip side, late or missed deliveries can leave customers frustrated, result in canceled orders, and harm long-term loyalty.

From a financial angle, delayed shipments can drive up costs. Companies might need to cover expedited shipping fees, keep extra inventory on hand, or even face penalties for failing to meet deadlines. Suppliers who reliably stick to delivery schedules can help businesses streamline inventory processes, cut down on rush-order expenses, and maintain stronger profit margins.

ForthSource provides brands and sourcing managers with tools to track on-time delivery performance using real-time metrics and a proprietary scoring system. This enables businesses to quickly pinpoint reliable suppliers and avoid unnecessary expenses.

Why should you monitor the Cost of Quality (CoQ) when assessing suppliers?

Monitoring the Cost of Quality (CoQ) plays a key role in uncovering hidden expenses linked to defects, rework, or non-compliance issues. By analyzing these costs, businesses can reduce risks, enhance supplier performance, and make smarter, more economical sourcing choices.

Keeping an eye on CoQ also sheds light on a supplier's ability to consistently uphold quality standards. This not only strengthens long-term partnerships but also helps prevent costly disruptions in the supply chain.