Supplier certifications can be misleading, and verifying their validity is critical to avoid financial, legal, and reputational risks. Here's what you need to know:

- Why Verification Matters: Fake or expired certifications are common and can lead to legal issues, customs delays, or damaged trust. Regulations like the EU's Green Claims Directive and FTC’s Green Guides demand stricter compliance.

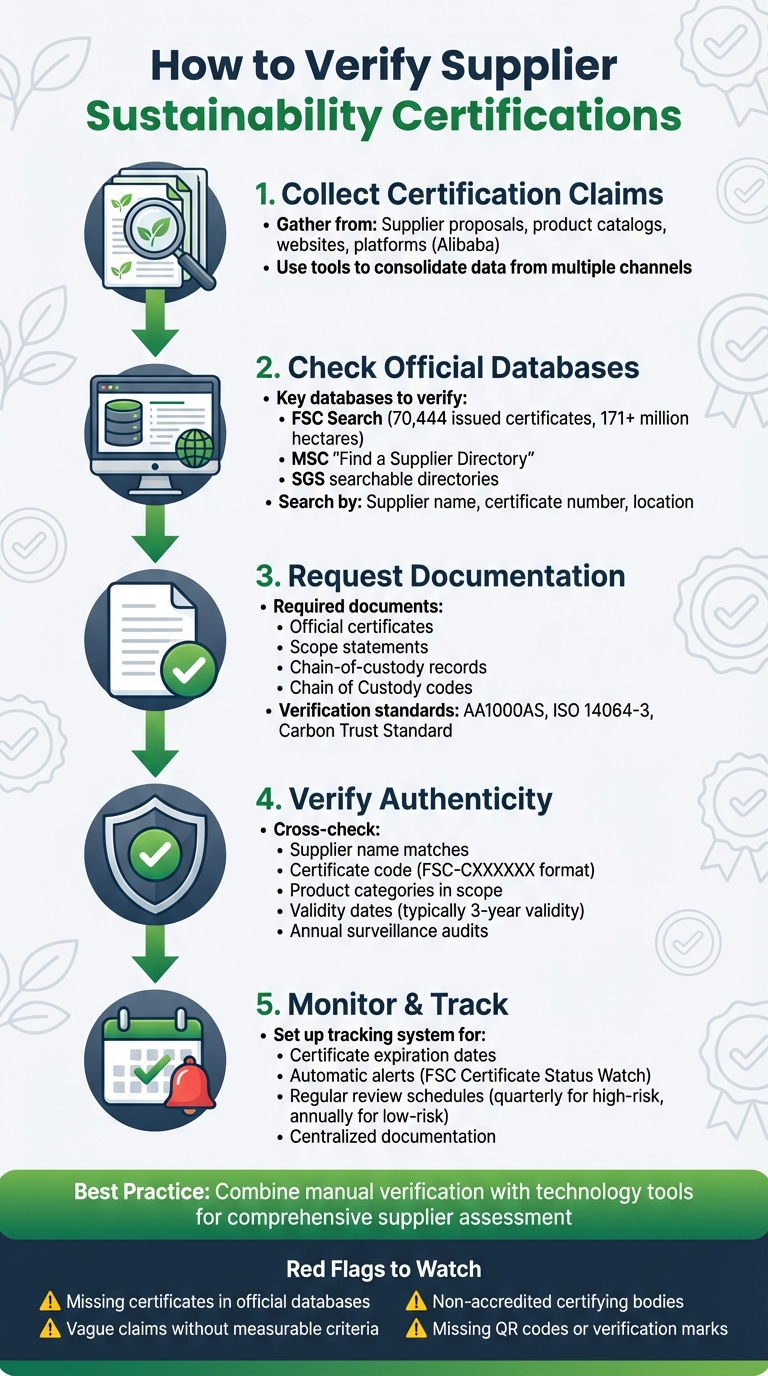

- Steps to Verify Certifications:

- Collect supplier claims systematically from proposals, catalogs, and platforms.

- Use official databases (e.g., FSC, MSC) to confirm certificate details like scope, validity, and issuing body.

- Request official documents, including scope statements and chain-of-custody records.

- Spotting Red Flags: Missing certificates, unverifiable claims, or unclear documentation are warning signs.

- Tools to Simplify the Process: Platforms like ForthSource streamline data collection, pre-screen suppliers, and track certifications efficiently.

Conclusion: Combine manual checks with technology to ensure certificates are valid and meet your requirements. This protects your brand from compliance issues and builds trust with consumers.

5-Step Process to Verify Supplier Sustainability Certifications

How Do You Verify Sustainable Material Claims?

Collecting and Organizing Certification Claims

Start by systematically gathering all supplier claims before diving into verification. Look through supplier proposals, product catalogs, websites, and platforms like Alibaba. Tools like ForthSource (https://forthsource.io) can help streamline this process by consolidating supplier data from multiple channels, making it easier to track everything in one place.

Finding Certification Claims from Suppliers

To verify supplier claims, turn to official certification directories. For instance, the Forest Stewardship Council (FSC) offers a search portal that lists 70,444 issued certificates, covering over 171 million hectares of certified forests. Similarly, the Marine Stewardship Council (MSC) provides a "Find a Supplier Directory" to locate suppliers with MSC Chain of Custody certificates. SGS also has searchable directories where you can verify information using client names, certificate numbers, or product details.

It’s important to confirm that a certification’s scope aligns with your specific product. For example, a supplier may hold an FSC Forest Management certification for their operations, but that doesn’t necessarily mean the products you’re purchasing carry an FSC Chain of Custody certification. MSC certifications, on the other hand, come in various forms, such as Default, Group, or Consumer-Facing Organization Chain of Custody versions.

Once you’ve verified claims, request additional documentation from suppliers to ensure everything checks out.

Requesting Documentation from Suppliers

After identifying certifications, ask suppliers for official certificates, scope statements, and chain-of-custody records. Be specific about the verification standard you need, such as AA1000AS, ISO 14064-3, or Carbon Trust Standard. Be cautious if a supplier only provides "agreed upon procedures", "pre-assurance", or internal verification, as these methods lack the robust third-party confirmation required. For added traceability, request Chain of Custody codes that directly link the certification to the products in question.

Keep all documentation organized for easy access and future reference.

Creating a Certification Tracking System

Set up a tracking system to log key details, including supplier names, claimed certifications (with type and scope), certificate numbers, certifying bodies, and issuance and expiration dates. Many certifications are valid for three years but require annual surveillance audits, so keeping an eye on expiration dates is crucial. To make the process even smoother, download time-stamped PDFs from certification portals like FSC Search or SGS directories. This centralized system not only speeds up future verification but also helps identify gaps or inconsistencies before they turn into problems.

Verifying Certification Authenticity

Once you've gathered the necessary documentation, the next step is to confirm the authenticity of the certifications. Begin by visiting official databases managed by certifying organizations. For example, you can use FSC Search at search.fsc.org to validate certificates. These databases allow you to search by supplier name, certificate number, or location, giving you access to official records. From there, compare the certificate details with the certifying body's database to ensure everything matches accurately.

Cross-Checking Certificates with Certifying Bodies

Take the certificate details provided by your supplier and compare them with the information listed in the certifying body’s database. Confirm key details such as the supplier’s name, certificate code (e.g., FSC-CXXXXXX or XX-COC-000000), and the specific product categories covered. For example, if you're sourcing paper products, make sure the certificate explicitly includes "paper" in its scope rather than just general forest management. Additionally, verify that the certifying body itself is properly accredited by checking with the relevant oversight organization.

Checking Certificate Validity and Scope

Ensure the certificate is valid by checking its current status, expiration date, and renewal cycle. Confirm that it applies to the specific sourcing facility you’re working with, rather than just the supplier's parent company. Keep official records of these verifications for future audits.

When reviewing sales documents, delivery notes, and invoices, they should clearly identify certified products, include the certification claim (e.g., "FSC Recycled" or "FSC 100%"), and display the supplier’s certificate code. Missing or unclear information on these documents should raise a red flag and warrant further investigation.

Using Technology for Risk Assessment

After verifying certificate details and validity, consider using technology to evaluate supplier risk. Tools like ForthSource's credibility scoring can streamline this process by combining manual checks with automated assessments. ForthSource aggregates data points such as legal reports and WeChat verification to highlight potential risks early, saving you time. This pre-screening step is especially useful when assessing multiple suppliers, allowing you to focus your manual verification efforts on the most reliable candidates.

For ongoing monitoring, tools like FSC's "Certificate Status Watch" can be invaluable. This service sends automatic email alerts if a supplier’s certificate is suspended or terminated after a 14-day grace period. These notifications help you stay informed and act promptly if any issues arise.

sbb-itb-633367f

Spotting Red Flags in Supplier Certifications

Common Fraud Patterns to Watch For

Fraudulent sustainability certifications tend to follow certain patterns, making them easier to spot if you know what to look for. One major red flag is missing or invalid certificates. For example, if a supplier claims to have an FSC certificate, but it’s absent from the official database, that’s a clear warning sign. Similarly, eco-labels that lack clear, measurable standards should raise concerns. Bureau Veritas has emphasized that exaggerated or false environmental claims can not only harm a company's reputation but also lead to legal issues. Phrases like "eco-friendly" or "green" without scientific evidence or measurable criteria are especially suspect. Additionally, certifications issued by non-accredited bodies often lack legitimacy and should be approached with caution.

Transparency - or the lack of it - is another key indicator. In December 2025, SGS introduced its Supplier Verification Program, which provides verified suppliers with an "SGS Verified Supplier mark" linked to a QR code for easy access to verification summaries. If a supplier claims to have SGS verification but cannot provide this mark or if the QR code doesn’t work, it’s a strong signal that something might be amiss. Another tactic to watch out for is hidden trade-offs, where a positive claim about one aspect of sustainability is used to distract from negative impacts elsewhere.

Once these red flags are identified, the next step is deciding how to verify certifications effectively - whether through manual methods, technology, or a blend of both.

Manual vs. Technology-Assisted Verification

When it comes to verifying supplier certifications, you have two main approaches: manual checks or technology-driven tools. Each has its strengths and weaknesses, but combining the two can provide the most thorough results.

Manual verification relies on human expertise to identify subtle inconsistencies or irregularities. While this method can catch details that automated tools might overlook, it’s time-intensive and difficult to scale, especially when managing a large network of suppliers. On the other hand, technology-assisted verification - like the solutions offered by ForthSource - streamlines the process. These tools can quickly flag discrepancies in supplier data using methods like legal report integration and credibility scoring.

| Aspect | Manual Verification | Technology-Assisted Verification |

|---|---|---|

| Speed | Slow; requires detailed manual review | Fast; performs real-time checks |

| Fraud Detection | Relies on human expertise | Automatically identifies inconsistencies |

| Scalability | Limited to smaller supplier networks | Efficiently handles large supplier pools |

| Accuracy | Prone to human error | High accuracy in data validation |

| Cost | Labor-intensive and costly | Reduces costs with automation |

| Audit Trail | Manual and inconsistent record-keeping | Automated and centralized tracking |

The best strategy often combines these approaches. Technology can handle the heavy lifting by pre-screening suppliers and highlighting potential issues. Then, manual expertise can step in to thoroughly investigate flagged concerns. This balanced method ensures a more reliable and efficient way to maintain supplier integrity while minimizing risks.

Building a Repeatable Verification Process

Adding Verification to Procurement Policies

Incorporate certification requirements directly into all supplier-related documents, from Requests for Quotation (RFQs) to contracts and supplier management guidelines. Be explicit: if ISO 14001 certification is required, clearly state it and ensure suppliers provide valid, authentic documentation. Many global companies already include ISO 14001 certification as a standard part of their sustainability-focused procurement policies.

Include clauses that mandate third-party verification or audits during both the onboarding process and ongoing supplier management. Clearly outline what steps will be taken if a supplier fails to meet certification standards - having a defined corrective action plan avoids confusion. Additionally, establish clear record-keeping protocols to ensure all verification activities and certification documents are properly documented. A "Supplier Onboarding Checklist" that integrates these certification verification steps can help ensure no details are overlooked.

Finally, assign accountability by designating team members and setting up regular review schedules to enforce these policies.

Assigning Roles and Setting Review Schedules

Appoint team members who are well-versed in both sustainability standards and your company’s procurement processes. Use a risk-based approach to schedule reviews that align with certificate expiration dates. For instance, high-risk suppliers may require quarterly reviews, while lower-risk vendors could be reviewed annually. For more complex verifications, consider working with accredited Certification Bodies to conduct audits and checks.

A sustainability manager or dedicated team should maintain up-to-date documentation and performance records. Keep in mind that certifications are not indefinite - they need periodic updates, making continuous monitoring a critical part of the process.

Using Technology to Track Certifications

Once roles are assigned and schedules are in place, leverage technology to simplify certification tracking. Building on earlier discussions about technology in pre-screening, use digital tools to centralize certification data. These platforms make it easier to track certifications, standardize reporting, and streamline audits. For instance, systems that use QR codes, such as SGS's Supplier Verification Program, provide quick access to verification summaries and tracking information. Automating data tracking ensures ongoing compliance with minimal effort.

Platforms like ForthSource offer practical solutions for managing verified certifications while assessing supplier credibility in real time. Its composite scoring system evaluates suppliers based on factors like pricing, credibility, WeChat data, and legal reports, giving you a well-rounded view of supplier reliability. By centralizing all certification records and eliminating the need for multiple spreadsheets, this technology helps flag potential issues before they escalate. Plus, it creates an immutable audit trail, reducing the manual workload for your procurement team.

Conclusion

Ensuring supplier certifications are genuine demands ongoing effort and attention. It’s not just about collecting claims but also verifying them through trusted databases like FSC Search or SGS directories. Spotting warning signs of fraudulent documentation is equally important, as each step strengthens your ability to make informed sourcing decisions.

The best verification strategies combine human expertise with the efficiency of technology. Manual audits and expert evaluations dig deep to uncover sophisticated fraud and confirm a supplier’s operational capabilities. At the same time, technology tools simplify the initial screening process, flag potential issues, and keep certification records organized for quick access. This combination creates a system where every piece of information works together to safeguard your brand.

ForthSource enhances this process by merging certification tracking with real-time assessments of supplier credibility, making your supply chain more reliable. Incorporating a repeatable verification process into your procurement policies ensures consistency across your operations. For more complex evaluations, independent third-party organizations like SGS, Bureau Veritas, and BSI can take on the heavy lifting, leaving your internal team free to focus on enforcing policies and maintaining regular oversight.

FAQs

How can I check if a supplier's sustainability certification is genuine?

To confirm a supplier's sustainability certification, begin by reviewing the certifying organization’s official registry. Search for details such as the certificate number, expiration date, and auditor information to verify they align with what the supplier has provided. For added assurance, reach out to the certifying body directly to validate the certificate's legitimacy. Watch out for warning signs like blurry or poorly designed logos, missing signatures, or mismatched details on the document. These steps can help you ensure the certification is both genuine and reliable.

What are the best ways to verify supplier sustainability certifications?

Verifying supplier sustainability certifications is essential for promoting transparency and building trust. Thankfully, several tools and platforms are available to make this process more efficient:

- SGS Supplier Verification Program: Conducts on-site audits and issues a QR-code-linked badge for real-time verification of supplier credentials.

- Forest Stewardship Council (FSC): Provides a certificate search portal and email notifications to track changes in certification status.

- Cascale Higg Facility Environmental Module: Focuses on verifying self-reported environmental data in the apparel and textile industries.

- SCS Global Services: Manages over 100 certification programs, including the Global Recycled Standard and Carbon Neutral Certification.

- SupplierGateway: Centralizes digital certificate validation alongside sustainability assessments.

Platforms like ForthSource further simplify the process by consolidating supplier data and offering real-time credibility indicators, such as verified certifications. This makes it easier for sourcing managers to validate supplier claims quickly, without the need for direct communication, saving both time and reducing potential risks.

Why is it important to confirm what a supplier's certification actually covers?

When you confirm the scope of a supplier’s certification, you ensure that the claimed sustainability standard directly applies to the specific products, materials, or processes you intend to source. This step helps you steer clear of misleading claims while ensuring the supplier meets the required sustainability criteria.

By digging into these details, you can confidently determine if the supplier aligns with your company’s ethical and environmental goals. This also minimizes risks such as greenwashing or failing to comply with industry regulations.