- Key Causes of Disputes: Quality issues, late deliveries, pricing changes, communication gaps, and intellectual property concerns.

- Resolution Methods: Direct negotiation, mediation, arbitration, or litigation. Arbitration is often preferred for enforceable and quicker outcomes.

- Preventive Measures:

- Conduct background checks on suppliers' financial health and operations.

- Use milestone-based payments tied to production progress.

- Draft clear contracts with detailed quality standards, payment terms, and dispute resolution clauses.

- Improving Communication:

- Document all agreements and use bilingual contracts.

- Hold regular check-ins and use visuals to clarify expectations.

- Understanding Business Practices: Building trust and relationships (guanxi) is critical. Respect hierarchy and avoid direct blame to maintain productive partnerships.

The focus is on preventing disputes through solid contracts, clear expectations, and regular communication while resolving conflicts efficiently when they arise.

How to deal with Chinese Suppliers?

Cultural Awareness and Communication Methods

Grasping Chinese business culture is key to avoiding disputes and resolving conflicts effectively. Even small cultural differences can spiral into larger issues if not handled thoughtfully. By fostering strong relationships and maintaining open communication, businesses can create a smoother path for operations and quicker resolutions when challenges arise. Below, we explore how cultural understanding and clear communication can make a significant difference in dispute resolution.

Understanding Guanxi and Building Relationships

Guanxi, a cornerstone of Chinese business culture, refers to networks of relationships built on mutual trust and obligation. Unlike transactional approaches, guanxi emphasizes personal connections and long-term partnerships, which often take precedence in decision-making.

Developing guanxi takes time and effort. Face-to-face interactions are highly valued, so investing in personal meetings with your Chinese partners can go a long way. Additionally, respecting the hierarchy within the organization is crucial. Always address concerns through your primary contact rather than bypassing them to reach senior management. Skipping this step can complicate discussions and hinder resolutions.

Another critical aspect is the concept of "saving face", which involves maintaining dignity and avoiding direct blame. For instance, instead of pointing fingers over quality issues, focus on collaborative problem-solving that benefits everyone. This approach fosters cooperation and prevents defensive reactions from your supplier.

Clear Communication Tips

Misunderstandings during disputes can be minimized by adopting straightforward and thoughtful communication practices:

- Document Everything: Follow up verbal agreements with detailed emails that outline the discussion, agreements made, and next steps. This creates a clear record and reduces the risk of confusion.

- Use Simple Language: Avoid idioms, slang, or overly technical terms. Instead, use specific examples and clear, concrete language to explain your expectations or concerns.

- Bilingual Communication: Translating key documents - such as contracts, technical specifications, and quality requirements - into Chinese shows respect for your supplier's language and reduces the likelihood of misinterpretation.

- Respect Time Zones: Schedule meetings at times that work for both parties, and allow reasonable time for responses to emails. Rushing decisions due to time zone differences often leads to errors and miscommunication.

- Leverage Visual Aids: Photos, diagrams, and other visual tools can clarify product specifications or quality concerns far better than lengthy written descriptions. They eliminate ambiguity and ensure everyone is on the same page.

Regular Check-ins and Meetings

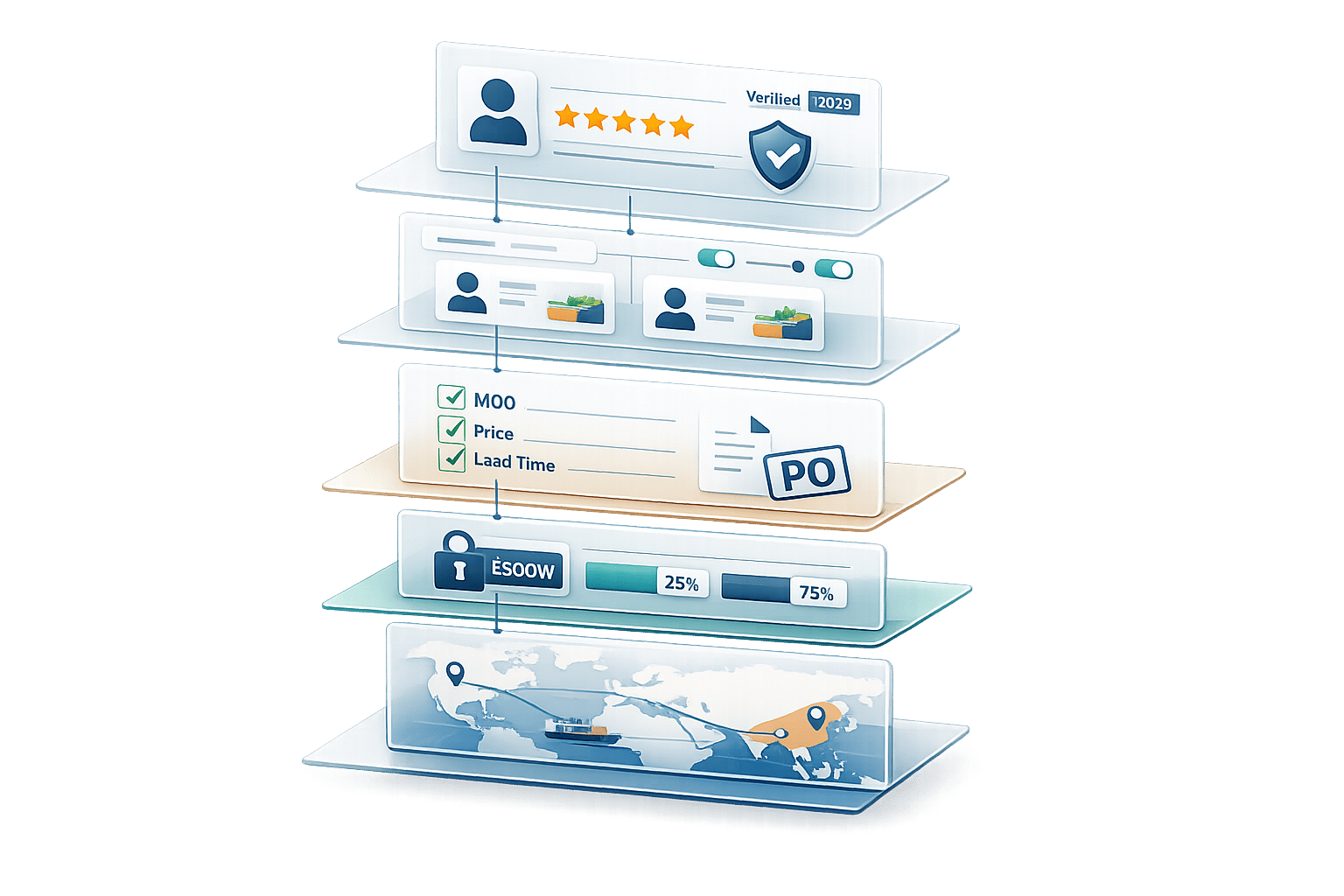

Consistent communication through scheduled check-ins helps address potential issues before they escalate. Biweekly video calls and milestone reviews at key progress points - such as 25%, 50%, and 75% completion - are particularly effective for keeping projects on track.

Annual in-person visits to your supplier’s facilities are another great way to strengthen relationships. These visits allow you to meet the team, understand their production processes, and identify any potential challenges early.

Being mindful of the Chinese cultural calendar is also important. Planning around holidays and cultural events shows respect and prevents unnecessary delays or scheduling conflicts.

Lastly, proactive discussions about market conditions, material costs, or production constraints can help smooth out minor issues before they grow into larger problems. These regular conversations also reinforce trust and collaboration, paving the way for a more successful partnership.

Writing and Enforcing Contracts

A well-crafted contract not only minimizes misunderstandings but also strengthens your position if disputes arise. It lays out clear expectations and provides a roadmap for resolving issues. Below, we’ll break down key elements of a strong contract and explore effective methods for handling disputes.

Key Parts of a Strong Contract

Payment Terms and Conditions:

Clearly define payment terms by linking them to specific deliverables and milestones. Specify key project benchmarks and include penalties for late delivery. Also, outline acceptable payment methods, such as wire transfers or letters of credit, to avoid confusion.

Quality Standards and Inspection Procedures:

Set measurable quality benchmarks with detailed tolerances, testing methods, and acceptance criteria. Clearly state who will conduct inspections and at what stages - whether pre-production, during production, or before shipment - to ensure the final product meets the agreed standards.

Intellectual Property (IP) Protection Clauses:

Protect your designs, specifications, and proprietary data by including robust IP clauses. Specify that all intellectual property remains yours and require confidentiality agreements. Since Chinese law often follows a "first-to-file" principle, register your trademarks and designs in China before production begins.

Force Majeure and Liability Limits:

Prepare for unforeseen events by including force majeure clauses and defining liability limitations. This ensures both parties understand their obligations in exceptional circumstances.

Dispute Resolution Clauses:

Detail a step-by-step dispute resolution process, starting with direct negotiation, followed by mediation, and finally arbitration if needed. Specify the governing law that will apply to the contract to avoid ambiguity.

Dispute Resolution Options

Direct Negotiation:

For smaller issues like slight quality inconsistencies or delivery delays, direct negotiation is often the quickest and least expensive option. Document all agreements during this process to prevent future misunderstandings.

Mediation:

When direct negotiation doesn’t suffice, mediation can be a valuable next step. A neutral third party helps both sides reach an agreement, often preserving the business relationship. Many organizations specialize in mediation services for international trade disputes.

Arbitration:

Arbitration is a more formal and binding process, offering enforceable resolutions. However, it’s essential to carefully choose the arbitration venue and rules, as this method may involve higher costs and take more time compared to negotiation or mediation.

Litigation in Chinese Courts:

Litigation should be considered a last resort due to its complexity and potential for lengthy proceedings. While recent reforms have aimed to improve efficiency in Chinese commercial courts, pursuing litigation often requires significant time and resources.

Working with Local Legal Experts

A strong contract is only as effective as its enforceability. Consulting local legal experts ensures your contract aligns with Chinese laws and business practices, reducing risks of unenforceable clauses or misunderstandings.

Leveraging Local Counsel:

Local legal professionals can adapt your contract to fit within the Chinese legal framework. For example, penalty clauses common in Western contracts may not hold up in Chinese courts unless properly revised. Additionally, local counsel can provide invaluable support during disputes, thanks to their understanding of local customs and connections with arbitrators or court officials. When hiring legal experts, prioritize those with experience in international trade disputes and discuss their fees upfront to avoid surprises.

sbb-itb-633367f

Prevention Methods to Avoid Disputes

The smartest way to handle supplier disputes? Stop them before they start. Choosing the right supplier with care can save you time, money, and headaches. By taking a proactive approach, you can reduce the chances of issues arising in the first place. Here are a few strategies to help you stay ahead of potential problems.

Complete Supplier Background Checks

Rushing into a supplier partnership without doing your homework can lead to unnecessary trouble. A thorough background check can reveal potential red flags and ensure you're working with a reliable partner. Here's what to focus on:

Financial Stability Assessment:

Ask for financial records from the past two to three years. Look for steady revenue, manageable debt, and enough working capital. Suppliers with shaky finances might cut corners on quality or miss delivery deadlines when cash flow is tight.

Operational Capabilities Review:

Visit their facilities or hire a third-party auditor to evaluate their production capacity, quality control measures, and overall efficiency.

Reference Verification:

Reach out to at least three of their current or recent clients. Find out how dependable they are with deliveries, the consistency of their product quality, how they handle issues, and how responsive they are in communication.

Certification and Compliance Checks:

Make sure they have the proper certifications (like ISO 9001) and meet industry and environmental standards. This protects your business and reputation.

By covering these bases, you can avoid many of the quality and communication issues that often lead to disputes.

Setting Up Milestone Payment Terms

Milestone payments are a great way to protect your finances while keeping your supplier motivated. Instead of paying a large sum upfront, link payments to specific deliverables. This approach aligns the supplier’s incentives with your project goals and gives you leverage if problems arise.

Payment Structure:

For instance, you could pay 30% when the order is confirmed, 40% upon production completion, and the remaining 30% after final inspection and before shipment. Adjust the percentages based on your comfort level and the supplier's reliability. For newer or higher-risk suppliers, hold back a larger portion until the final delivery.

Quality Gates:

Tie payments to specific checkpoints, such as production milestones or quality inspections.

Documentation Requirements:

Clearly outline what documentation (like test reports or shipping details) is needed for each payment stage.

Penalty Clauses:

Include penalties for missed milestones or quality issues. These should be reasonable but firm enough to incentivize the supplier to prioritize your project and meet deadlines.

This payment structure not only minimizes financial risk but also helps avoid the pricing disagreements and delivery delays that are common in supplier relationships.

Using Data-Driven Platforms

Tools like ForthSource can dramatically reduce supplier-related risks by offering deeper insights than traditional directories. These platforms combine data and analysis to help you make smarter decisions and build stronger partnerships.

ForthSource, for example, goes beyond just listing suppliers. It aggregates products from platforms like Alibaba and AliExpress and uses a proprietary scoring system to evaluate suppliers on factors like pricing, reliability, and customer sentiment.

Credibility Scoring:

These platforms analyze multiple data points, such as transaction history, customer feedback, and operational metrics, to score suppliers. This helps you identify dependable partners while avoiding potential risks.

Sentiment Analysis:

By analyzing customer reviews, these tools provide insights into a supplier's reliability, communication, and problem-solving abilities. This is especially useful for understanding how they handle challenges.

Domain Trust Metrics:

Platforms assess the legitimacy of suppliers by reviewing their business verification status, website credibility, and online consistency. This helps you steer clear of fraudulent suppliers who might disappear after payment.

Direct Access:

Unlike traditional sourcing methods that involve intermediaries, these platforms often provide direct access to supplier details. This eliminates extra fees and communication barriers, giving you more control over the relationship.

Comparing Dispute Resolution Methods

When disputes arise with Chinese suppliers, understanding your resolution options is key to choosing the approach that works best for your situation.

Resolution Methods Comparison Table

Here’s a quick overview of four common dispute resolution methods in China:

| Method | Description |

|---|---|

| Mediation | A flexible process where a neutral third party helps the parties find a mutually agreeable solution. |

| Arbitration | A formal process resulting in a binding decision, handled outside of public courts. |

| Litigation | The conventional court process that leads to enforceable legal judgments. |

| Online Dispute Resolution (ODR) | A modern approach using digital platforms, offering outcomes with the same legal authority as traditional methods. |

Each method has its own strengths. Mediation works well for fostering compromise in a non-adversarial setting. Arbitration delivers binding decisions efficiently, avoiding the public nature of court proceedings. Litigation, while more time-intensive, relies on the judicial system to enforce legal judgments. Online dispute resolution introduces convenience through digital platforms, maintaining the same legal weight as traditional approaches.

These methods can also complement one another. For instance, arbitration awards can be enforced through the courts, offering additional flexibility for complex cases. By combining these resolution strategies with proactive measures to prevent disputes, you can maintain smoother and more reliable supplier relationships.

Conclusion: Key Points and Next Steps

Dealing with disputes involving Chinese suppliers calls for a mix of prevention, preparation, and consistent communication. The best strategy is to focus on avoiding conflicts altogether rather than getting bogged down in resolution processes later.

Start with the basics: conduct thorough background checks, use milestone payments, and enforce detailed inspection requirements. These steps help minimize risks early on. Additionally, clear bilingual contracts with strong arbitration clauses are crucial. Since Chinese courts generally uphold arbitral awards under the New York Convention, this approach ensures your agreements are enforceable when disputes arise.

Understanding cultural nuances also plays a big role in navigating challenges. Regular check-ins, well-documented processes, and open communication channels can help you spot and address potential problems before they escalate.

When disputes do occur, arbitration often delivers better results for U.S. companies compared to litigation. Chinese courts tend to encourage conciliation, reflecting a cultural preference for resolving conflicts through negotiation rather than confrontation. Partnering with local legal experts can further enhance the enforceability of your contracts.

Looking ahead, focus on strengthening your supplier relationships. Here’s where to start: review your current contracts to ensure they include clear dispute resolution clauses favoring arbitration. Set up regular supplier performance evaluations and establish standardized communication protocols. You might also explore tools like ForthSource, which uses real-time credibility scoring and quality indicators to help you identify reliable partners from the beginning.

The ultimate goal isn’t just to resolve disputes - it’s to build partnerships that prevent them. By combining cultural awareness, airtight contracts, and smart technology, you can create a sourcing strategy that supports your business growth while keeping risks in check.

FAQs

How can I make sure my contract with a Chinese supplier is legally enforceable in China?

To make sure your contract with a Chinese supplier holds up legally, you need to draft it with precision and align it with Chinese law. Specify Chinese jurisdiction and venue in the agreement, and ensure the contract is bilingual (Chinese and English). This helps prevent misunderstandings and makes enforcement much smoother.

Your contract should also be crystal clear, detailed, and follow the guidelines set out in the Chinese Civil Code, which has been the foundation of contract law since 2021. To further solidify its enforceability, include specific terms for resolving disputes, such as arbitration or mediation, within the framework of China’s legal system.

What cultural differences should I consider when negotiating with Chinese suppliers?

When working with Chinese suppliers, it's important to recognize that building relationships and trust often takes priority over diving straight into the details of a deal. Taking the time to create a genuine connection can play a big role in how successful your negotiations turn out.

Another key difference to keep in mind is how contracts are viewed. Chinese suppliers often see contracts as flexible guidelines, not set-in-stone commitments. This contrasts with the Western perspective, where a contract is typically considered final and binding. To navigate this difference, stay open to renegotiations and keep communication flowing.

By appreciating these cultural distinctions and focusing on mutual understanding, you can strengthen your partnerships and minimize potential misunderstandings.

How can milestone-based payments help reduce disputes with Chinese suppliers?

When working with Chinese suppliers, milestone-based payments can help minimize disputes and keep projects on track. By tying payments to specific, measurable deliverables, both you and your supplier can stay aligned on expectations and avoid misunderstandings. This method ensures suppliers are paid only after achieving agreed-upon milestones, promoting accountability and timely results.

Beyond protecting your investment, this approach encourages open communication and builds trust throughout the partnership. Clear terms make it easier to address potential issues early, reducing the risk of conflicts. All in all, milestone-based payments can make supplier relationships run more smoothly.