Smart technology is reshaping supplier discovery, cutting time and costs while improving decision-making. AI and machine learning now handle tasks that once required weeks of manual effort, such as evaluating supplier stability, ratings, and sustainability. Businesses using these tools report faster sourcing (up to 90% quicker), cost reductions (15-45%), and improved risk management. For example, Siemens Energy identified 59 suppliers in 12 countries within four weeks using AI.

Key takeaways:

- Speed: AI-driven tools drastically reduce sourcing time.

- Efficiency: Data analytics optimize supplier selection and forecasting.

- Risk Reduction: Predictive insights flag issues early, avoiding disruptions.

- Cost Savings: Automating procurement cuts expenses by up to 30%.

Platforms like ForthSource combine AI with sentiment analysis and real-time data to simplify supplier comparisons, making it easier for brands to find reliable partners and maintain operations during challenges.

Alibaba.com’s AI-Powered Sourcing Tools Explained | Kuo Zhang’s Insights

Key Technologies Changing Supplier Discovery

Three main technologies are reshaping how businesses discover and evaluate suppliers: AI and machine learning, data analytics platforms, and sentiment analysis tools. Each plays a unique role in making sourcing more efficient and informed.

AI and Machine Learning

AI and machine learning have revolutionized supplier discovery by uncovering patterns and trends that are beyond human capacity to identify. These technologies can process massive amounts of data quickly, offering insights that save time and improve decision-making.

For instance, Veridion's AI-powered data engine collects updated information weekly on over 120 million suppliers across 240+ locations. This allows businesses to find niche suppliers that might otherwise go unnoticed in traditional databases. AI also automates repetitive tasks like sending RFIs, enabling teams to focus on strategic decisions.

Risk assessment is another area where AI shines. It evaluates factors like supplier stability, labor practices, and even environmental scores, helping companies make informed and responsible choices. For example, when Siemens faced a critical shortage of Surlyn - a specialized resin - its AI system analyzed import and shipping data to identify 150 potential distributors in just a few days.

AI also simplifies international sourcing by identifying local suppliers who meet compliance standards, reducing the guesswork involved in navigating regional regulations. For DTC brands, this means quicker access to diverse supplier networks, enabling faster market expansion.

While AI excels at processing data, data analytics takes it a step further by turning this information into actionable insights.

Data Analytics for Real-Time Decisions

Data analytics transforms raw data into meaningful insights, enabling businesses to make smarter, faster decisions. By analyzing large datasets, companies can uncover trends, forecast demand, and optimize operations.

This technology supports various aspects of supply chain management, including inventory control, production scheduling, and supplier evaluation. It uses descriptive analytics to review past performance, predictive analytics to anticipate trends, and prescriptive analytics to recommend the best course of action.

One standout feature of real-time data analytics is its ability to prevent disruptions. Businesses can continuously track stock levels, avoiding costly stockouts or excess inventory. During supply chain disruptions, real-time insights provide early warnings, allowing companies to act quickly.

Take Tesla, for example - they monitor their battery suppliers in real time to ensure consistent production and avoid delays. In agriculture, companies use weather data and supplier histories to predict crop shortages and adjust sourcing strategies.

Despite its advantages, only 31% of companies frequently utilize real-time data, though 66% of supply chain leaders view it as vital for future success.

"Real-time supply chain visibility helps you detect potential issues before they arise. Live information allows for faster response times and more informed decision making, helping you mitigate risk across the supply chain as a whole." - QIMAone

For eCommerce businesses, this level of visibility is crucial for maintaining inventory during peak demand periods, ensuring customer satisfaction.

While data analytics provides quantitative insights, sentiment analysis offers a more human-centered perspective.

Sentiment Analysis and Trust Metrics

Sentiment analysis brings a qualitative edge to supplier discovery by assessing the emotional tone behind customer and partner feedback. By analyzing unstructured data - like social media posts, reviews, and public discussions - this technology helps businesses gauge supplier reputation beyond basic ratings.

For example, a tech retailer used sentiment analysis to evaluate smartwatch reviews. They discovered growing frustration over unreliable Bluetooth connectivity, prompting them to address the issue. In another instance, sentiment analysis revealed negative feedback about the setup process for a new laptop range, leading the company to improve its quick start guide.

Trust metrics often complement sentiment analysis by measuring specific supplier traits, such as responsiveness and flexibility. Studies show that products with five reviews are 270% more likely to be purchased than those with none, and reviews are especially influential for high-priced items.

"My belief is that the sentiment around a brand or website is its primary indicator of trustworthiness. This is why sentiment analysis is now part of SEO success." - Bruce Clay, Founder and President, Bruce Clay Inc.

For DTC brands, understanding supplier sentiment is critical. It directly impacts customer satisfaction and helps maintain brand trust, ensuring long-term success.

When combined, these technologies offer a comprehensive view of supplier performance and reliability, empowering businesses to make better sourcing decisions.

How ForthSource Improves Supplier Discovery

ForthSource combines cutting-edge AI and analytics into one seamless platform designed specifically for DTC brands. Instead of juggling multiple tools and manually comparing suppliers, it simplifies the entire process with three standout features.

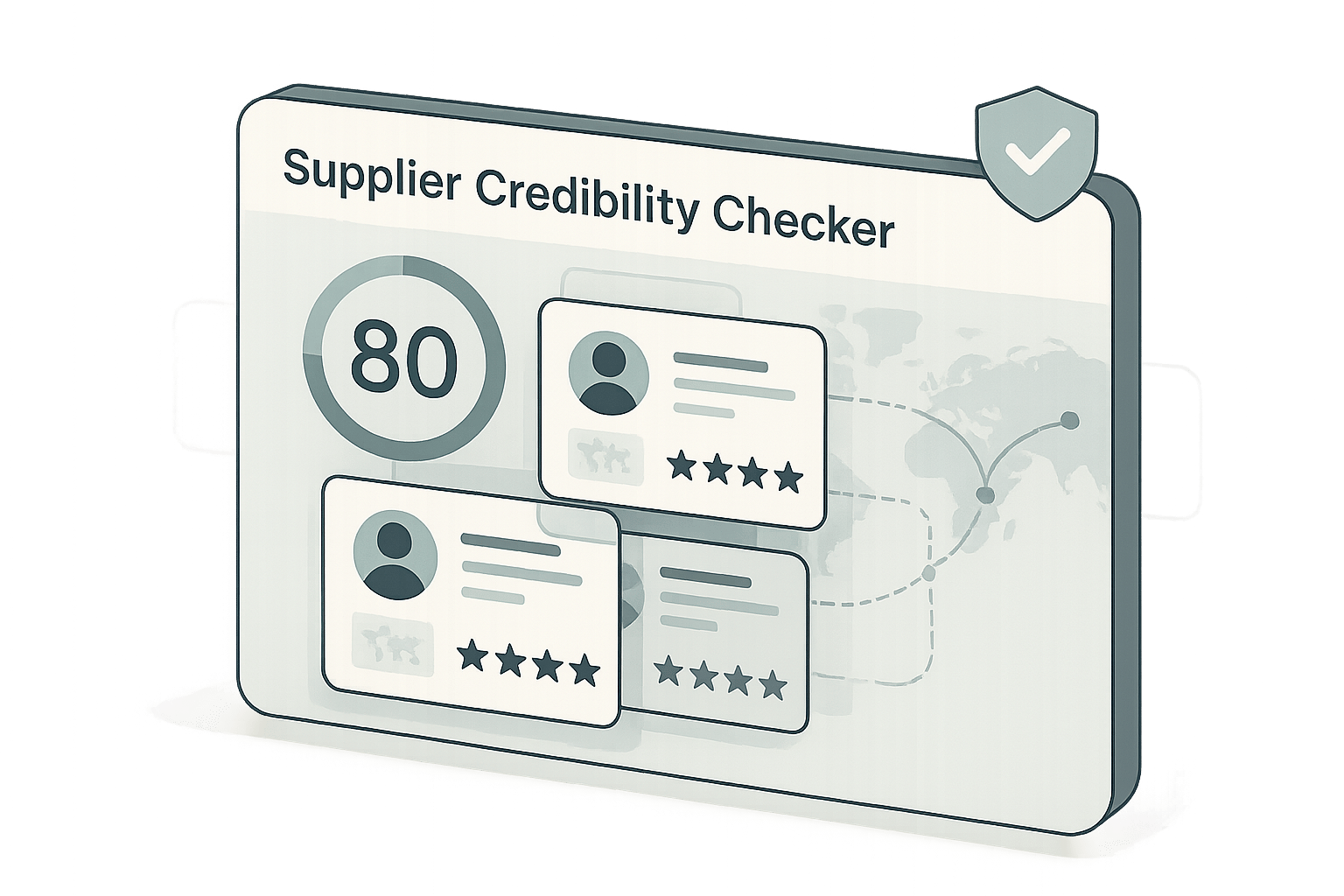

Composite Supplier Scoring

ForthSource's scoring system brings together key factors like price, domain reputation, review sentiment, and data quality into a single, easy-to-understand score. It evaluates suppliers across multiple dimensions, ensuring quotes reflect real costs, identifying suppliers with complete product data, and distinguishing trustworthy businesses from questionable ones. Sentiment analysis from sources like Google Reviews and Trustpilot adds another layer of insight into supplier reliability.

This approach delivers real-world benefits. Alex Chan, Supply Lead at Luma Goods, shared:

"We cut sourcing time by 40% using Forthsource's scoring system. Game changer."

The score updates in real time as new information becomes available, ensuring sourcing managers always have up-to-date metrics to guide their decisions.

Side-by-Side Supplier Comparisons

ForthSource also simplifies comparisons by offering a side-by-side view of suppliers from platforms like AliExpress, Alibaba, and DHGate - all in one interface. This feature standardizes metrics, allowing users to evaluate trust scores, pricing, and delivery times without switching between sites. By cross-referencing data from over 50 supplier platforms and layering in smart scoring and sentiment analysis, ForthSource ensures meaningful and actionable comparisons.

This tool is especially useful for DTC brands sourcing private label or custom products. It not only helps identify suppliers that meet specific needs but also flags potential risks before any commitments are made.

Direct Access Without Intermediaries

ForthSource goes a step further by providing direct access to supplier product pages through its platform-free workspace. By cutting out intermediaries, businesses can maintain privacy, shorten lead times, and gain more control over their sourcing strategies. This direct model lets sourcing managers communicate directly with manufacturers, negotiate terms without broker markups, and build long-term relationships.

Additionally, transparent pricing - free from hidden fees - helps businesses make accurate budget projections. This is particularly critical for DTC brands working to balance tight margins with quality and reliable delivery schedules.

Main Benefits of Smart Supplier Discovery for eCommerce

Smart technology brings a wealth of advantages that go beyond basic automation, reshaping how eCommerce businesses manage supplier relationships and tackle risks. These tools are changing the game by driving profits and improving operational efficiency.

Faster Sourcing and Improved Efficiency

AI-powered tools have revolutionized the sourcing process, cutting search times by more than 90%. What once took months can now be completed in just days - or even hours. According to McKinsey, traditional supplier searches often take up to three months, but AI simplifies this with a 30% boost in procurement efficiency.

Consider Siemens Energy's experience in late 2022. Faced with stricter regulations in Germany, the company needed new suppliers for photovoltaic systems. Instead of relying on outdated methods, they turned to AI-powered supplier discovery. Within just four weeks, the system identified 59 suppliers across 12 countries, provided structured data for evaluation, and facilitated onboarding multiple new partners.

"AI-driven technology is here to save the day by enabling quick reactions to supply chain disruptions."

– Michael Klinger, Siemens' Senior Director of Supply Chain Excellence

These advancements free up sourcing teams to focus on strategic initiatives rather than manual tasks. Companies using AI-driven supplier management tools have also seen a 30% improvement in supplier collaboration and innovation. Beyond speed, this efficiency lays the groundwork for safer and more cost-effective sourcing strategies.

Risk Reduction with Proactive Insights

While faster sourcing streamlines operations, smart technology also strengthens risk management. Instead of reacting to problems, AI enables proactive risk prevention. By analyzing vast amounts of data - ranging from financial records to performance history and news mentions - AI can detect potential risks early. This comprehensive approach addresses threats like financial instability, compliance issues, and cybersecurity vulnerabilities.

The importance of robust risk management became clear during recent supply chain crises. Events like the 2020 SolarWinds cyberattack and the COVID-19 pandemic exposed how supplier risks can ripple through entire networks. Similarly, the Colonial Pipeline cyberattack in 2021 highlighted the need for incident response protocols tied to supplier-related risks.

Modern tools use real-time monitoring and predictive analytics to stay ahead of such challenges. For instance, Moody's tracks over 570 million companies globally, offering dynamic risk assessments. Their Supplier Performance Risk scores cover 480 million suppliers, while Sustainability scores are available for 91 million suppliers. This level of coverage allows for detailed risk evaluations that would be impossible to achieve manually.

"Our unique Supplier Risk quantitative scorecards can help you anticipate disruption, prioritize risk challenges, and choose mitigation strategies that suit your company's risk tolerance and resource constraints - leading to resilient, efficient, and sustainable supply chains."

– Moody's

Adding to the complexity, regulatory changes occur frequently, with new sanctions imposed several times a day on average. AI-powered platforms continuously monitor these developments, giving procurement teams real-time alerts to prevent compliance issues from escalating.

Cost Savings Through Smarter Insights

AI-driven procurement doesn’t just save time - it also slashes costs. Companies leveraging AI in procurement have reported cost reductions of 15% to 45%, while eliminating up to 30% of the manual work typically required. These systems analyze data 90% faster than manual methods, allowing teams to focus on strategic priorities.

Digital procurement solutions can reduce process costs by 22–30%. Some organizations have even achieved savings of over 700% through online procurement strategies.

Take Walmart as an example. During a three-month pilot, the company used AI to negotiate with 100 suppliers. The results? Walmart exceeded its 20% target, reaching agreements with 64% of suppliers in just 11 days. The AI tool secured 1.5% savings and extended payment terms by 35 days. These successes led Walmart to expand the system's use for transportation rates, resale goods, and mid-tier supplier negotiations.

Workshops with a global manufacturer further illustrate the potential. An AI-enabled knowledge management tool improved search efficiency by 50% to 75%, an offer analysis tool cut work time in half, and a GenAI-powered tender assistant sped up the tender process by about 50%.

Over time, these savings grow as AI systems learn and refine their recommendations. They also help identify areas of maverick spending, opportunities for bulk purchasing, and better demand forecasting - reducing risks like overstocking or stockouts.

When combined, the cost savings, efficiency gains, and improved risk management highlight how smart supplier discovery is transforming eCommerce operations.

sbb-itb-633367f

Adding Smart Technology to Sourcing Workflows

Integrating smart technology into sourcing workflows isn't just about adopting new tools - it's about reshaping processes to meet clear objectives. Whether you're aiming to cut costs, improve quality, or better manage risks, the key is to align technology with your goals and adapt your workflows accordingly. Here's how to make it happen.

Step-by-Step Guide to Using Smart Tools

Start with defining your objectives. Are you looking to reduce expenses, speed up processes, or improve decision-making? Once you have a clear vision, evaluate your current procurement operations to identify areas where AI can make the biggest impact. For example, KIPP Nashville Public Schools transitioned from manual invoice processing to AI-driven systems, reducing approval times from a month to less than a week.

Choose tools that integrate seamlessly with your existing ERP systems. Precision Neuroscience saw a 50% boost in processing efficiency by doing just that. But technology alone isn’t enough - equip your team to use these tools as aids that complement their expertise, not replace it. Continuous monitoring and fine-tuning of these processes are essential. SAM Construction Group, LLC, for instance, used an automated procurement platform to implement control measures, securing early payment discounts from vendors.

Best Practices for Supplier Vetting

AI brings a new level of sophistication to supplier vetting by leveraging composite scoring, sentiment analysis, and real-time data. Begin by prioritizing the quality of your data - accurate, up-to-date, and complete information is critical. This is especially important since 82% of procurement professionals express concerns about the accuracy of their supplier data.

Adopt composite scoring systems that combine pricing, credibility, and sentiment data. ForthSource, for example, uses these methods to create detailed supplier profiles, uncovering risks that might otherwise go unnoticed. AI also enables continuous monitoring of suppliers, flagging changes in financial stability, compliance, or reputation.

Sentiment analysis from sources like Google Reviews and Trustpilot can provide additional insights into supplier reliability, offering a broader perspective than traditional metrics. However, human oversight remains crucial. AI is a tool to enhance human judgment, not replace it. As Henry Zhuang, Accounting Manager at Jumio, explains:

"The best practice is to have a purchase order first - the requisition needs to be approved before we receive the invoice. After we have a valid PO, we wait for the supplier to send us the invoice, and then we can match it to the PO and then make the payment. Tipalti has automated the entire process for us."

- Henry Zhuang, Accounting Manager, Jumio

Manual vs. AI-Driven Discovery Comparison

The advantages of AI-driven discovery become clear when compared to traditional manual methods. Here's how they stack up:

| Factor | Manual Discovery | AI-Driven Discovery |

|---|---|---|

| Speed | Weeks or months to identify suitable suppliers | Cuts discovery time by up to 50% (Samsung Electronics) |

| Accuracy | Prone to human error and limited insights | Delivers around 86% accuracy in risk predictions (BMW) |

| Cost | Higher labor costs and inefficiencies | Saves approximately 10% in procurement costs (Nestlé) |

| Risk Assessment | Reactive and based on historical data | Proactive, with predictive risk monitoring |

| Scalability | Resource-intensive to scale | Scales efficiently with automation and advanced analytics |

These comparisons highlight the transformative potential of AI in sourcing. For instance, BMW used machine learning models to predict supplier failures with 86% accuracy, leading to a 35% reduction in production disruptions. Similarly, Samsung Electronics halved the time required for supplier selection, and Nestlé achieved a 10% reduction in procurement costs. By shifting from reactive to proactive risk management, AI-driven systems not only streamline operations but also improve decision-making, setting a new standard for sourcing workflows.

Conclusion: Using Smart Technology for Better Sourcing

Let’s take a moment to reflect on how AI, data analytics, and sentiment analysis are reshaping supplier discovery and procurement for the better.

Smart technology has turned supplier discovery from a tedious task into a strategic advantage for DTC brands and sourcing professionals. By tapping into AI-driven tools, companies are achieving outcomes that were once out of reach with traditional methods.

One of the most striking benefits is speed. AI-powered solutions can accelerate supplier identification by over 90%, thanks to their ability to analyze critical attributes like financial stability, customer feedback, and sustainability metrics almost instantly.

But it’s not just about speed. These tools are also improving efficiency, cutting sourcing cycles by up to 30%. Take inventory optimization as an example - brands like Caraway are seeing potential revenue boosts of 40% by using AI-driven demand forecasting.

Perhaps the most game-changing benefit is risk reduction. With predictive analytics, AI can help companies anticipate and avoid supply chain disruptions before they happen, giving them a critical edge in today’s unpredictable market.

Platforms like ForthSource take this one step further by combining supplier scoring, real-time sentiment analysis, and direct marketplace access. This eliminates the need for middlemen and gives sourcing managers the insights they need to make confident, data-backed decisions.

In contrast, companies sticking with manual processes are falling behind. They face longer sourcing timelines, higher costs, and greater exposure to risks. On the flip side, those embracing smart technology gain the agility and precision needed to adapt to market shifts and stay competitive.

The bottom line? Sourcing managers who adopt AI-powered solutions now are setting the pace for the future of procurement, redefining efficiency, cost management, and risk mitigation in the process.

FAQs

How do AI and machine learning improve the supplier discovery process for businesses?

AI and machine learning are reshaping how businesses discover suppliers by sifting through massive amounts of data with speed and precision. These tools make it easier to spot reliable, low-risk suppliers, cutting down on the time it takes for procurement teams to make informed choices.

With predictive analytics, companies can evaluate supplier performance, foresee potential risks, and respond to market shifts as they happen. This forward-thinking approach builds confidence, simplifies sourcing, and enables teams to make decisions based on solid data, reducing guesswork and leading to better results.

How does sentiment analysis help assess supplier reliability and impact sourcing decisions?

How Sentiment Analysis Enhances Supplier Evaluation

Sentiment analysis plays a key role in assessing supplier reliability by diving into public feedback, reviews, and social media chatter. It helps sourcing managers get a clearer picture of a supplier's reputation, uncover potential risks, and measure trustworthiness.

With this technology, businesses can pinpoint suppliers who are dependable and pose minimal risk, while steering clear of those with negative reputations. The result? Smarter decision-making and stronger, more reliable supply chains that can better withstand challenges.

What challenges do businesses face when adopting smart technology for supplier discovery?

Integrating smart technology into supplier discovery workflows isn’t without its challenges. One major obstacle is data integration - bringing together information from multiple sources while ensuring it’s accurate and reliable. On top of that, businesses often face the technical complexity of setting up and managing AI systems, not to mention the ever-present concerns around data security.

Another hurdle comes from within: resistance to change. Employees may feel uneasy about adopting new systems, which can slow progress. And let’s not forget the high costs associated with implementing such advanced technology.

To navigate these roadblocks, companies need a solid plan, open communication, and a commitment to fostering trust in the technology throughout the organization.