Supplier rating systems are now essential for managing global sourcing challenges in 2025. With direct-to-consumer (DTC) e-commerce sales projected to hit $212.9 billion this year (a 16.6% increase from 2024), businesses face mounting pressure to ensure quality, timely delivery, and compliance while addressing consumer demands for transparency and sustainability. Poor supplier data alone costs organizations $12.9 million annually, further emphasizing the need for reliable tools.

Here’s what matters most when selecting a supplier rating system:

- Key Features: Prioritize systems with automated data collection, weighted scoring for performance (e.g., quality, delivery, cost, compliance), and real-time dashboards for monitoring.

- Ease of Use: Look for intuitive interfaces and seamless integration with existing tools to save time and reduce errors.

- Specialized Tools for U.S. Businesses: Ensure systems track compliance with U.S. regulations, handle currency conversion, and evaluate suppliers’ ability to scale production or meet sustainability goals.

- Emerging Trends: AI-powered scoring and predictive analytics are gaining traction, helping businesses anticipate risks and improve supplier relationships.

ForthSource stands out as a supplier discovery platform tailored for U.S.-based DTC brands. It simplifies supplier comparisons using automation, sentiment analysis, and secure data management, cutting sourcing time by up to 40%. Its freemium model allows businesses to explore features before committing to a subscription.

Key Takeaway: Supplier rating systems save costs (3–8%), improve quality, and help mitigate risks. For DTC brands, tools like ForthSource streamline global sourcing while addressing modern consumer and regulatory demands.

Vendor Scorecards: Managing Vendor Performance

What to Look for in Supplier Rating Systems

Choosing the right supplier rating system can make a significant difference in your sourcing strategy. Companies with effective supplier performance management systems often see supply costs drop by 3–8%, while also improving quality and delivery reliability. The challenge lies in identifying the features that align best with your business needs.

Scoring Methods and Data Transparency

The backbone of any good supplier rating system is its scoring approach. The most effective systems evaluate suppliers based on four key performance areas: quality, delivery, cost, and compliance. These categories help determine whether a supplier can truly add value to your operations.

Modern systems often use a weighted scoring model, letting you prioritize what matters most to your business. For example, a direct-to-consumer (DTC) brand launching a new product may focus more on quality and on-time delivery, while a company focused on profitability might give more weight to cost efficiency.

Automation in data collection is a must. The best systems pull information directly from inspection reports, tracking tools, cost analyses, and compliance audits without relying on manual input. This automation not only saves time but also improves accuracy. In fact, suppliers with automated compliance reporting systems have been shown to reduce border clearance delays by 34%.

Transparency is equally important. Systems that clearly outline how scores are calculated help build trust. Vendor scorecards should rely on measurable, structured data, ensuring all suppliers are evaluated consistently. Consistency in scoring is vital for making fair and informed decisions. Beyond scoring, it’s essential to consider ease of use and integration capabilities.

User Interface and Workflow Integration

A supplier rating system won’t be effective if it’s difficult to use. The interface should be intuitive enough for your procurement team to navigate without needing extensive training, while still offering detailed insights for strategic decision-making.

Integration is another crucial factor, especially for U.S. businesses managing complex supply chains. Look for systems with pre-built API integrations that connect supplier data seamlessly across departments like procurement and finance. This eliminates the need for manual data entry and ensures everyone has access to the same, up-to-date supplier information.

For example, one company saved 1,750 accounts payable (AP) hours annually and reduced hiring costs by automating supplier management. Another company accelerated its monthly financial close by 40%, thanks to streamlined integrations.

Real-time dashboards are becoming a key feature in modern systems. These dashboards allow you to monitor supplier compliance, delivery performance, and documentation accuracy as events unfold, enabling you to address issues immediately. Systems with no-code automation tools can further simplify procurement processes.

For U.S.-based companies, some specific features can make these systems even more impactful.

Features for U.S. Businesses

U.S. businesses often face unique challenges that require specialized features in their supplier rating systems. With 81% of ecommerce leaders citing tariffs as a potential disruption to their international strategies, robust compliance tracking is a must. The right system should monitor regulatory adherence and flag compliance risks before they escalate into larger problems.

Currency handling is another critical feature for businesses involved in international sourcing. Systems should provide pricing in USD and track exchange rates to help with cost comparisons and budgeting.

Flexibility is also key when working with global suppliers. Your rating system should evaluate a supplier’s ability to scale production, adapt to specification changes, and respond quickly to urgent needs.

As consumer demand for transparency grows, integrating ESG (Environmental, Social, and Governance) criteria into your supplier rating system is becoming increasingly important. Modern systems should track and score suppliers on factors like environmental impact, labor practices, and governance standards.

For DTC brands, features that support nearshoring - such as tools for monitoring suppliers in Mexico and Central America - can be particularly valuable. Additionally, AI-powered scoring frameworks are emerging as a powerful tool. These systems use real-time financial, compliance, and ESG metrics to predict potential supplier issues. Suppliers using predictive maintenance platforms, for example, report 22% fewer production halts. These advanced tools can help businesses stay ahead in a rapidly changing supply chain landscape.

ForthSource: Supplier Discovery Platform

ForthSource is a supplier discovery platform tailored for U.S.-based DTC (direct-to-consumer) brands navigating the challenges of global sourcing. Unlike traditional directories that often involve intermediaries or hidden fees, ForthSource gives sourcing managers direct access to supplier product pages and equips them with data-driven insights for smarter decision-making.

One of the biggest hurdles for DTC brands is the time it takes to evaluate suppliers. ForthSource eliminates the need for manual comparisons, making the process faster without compromising on quality.

How ForthSource Simplifies Supplier Discovery

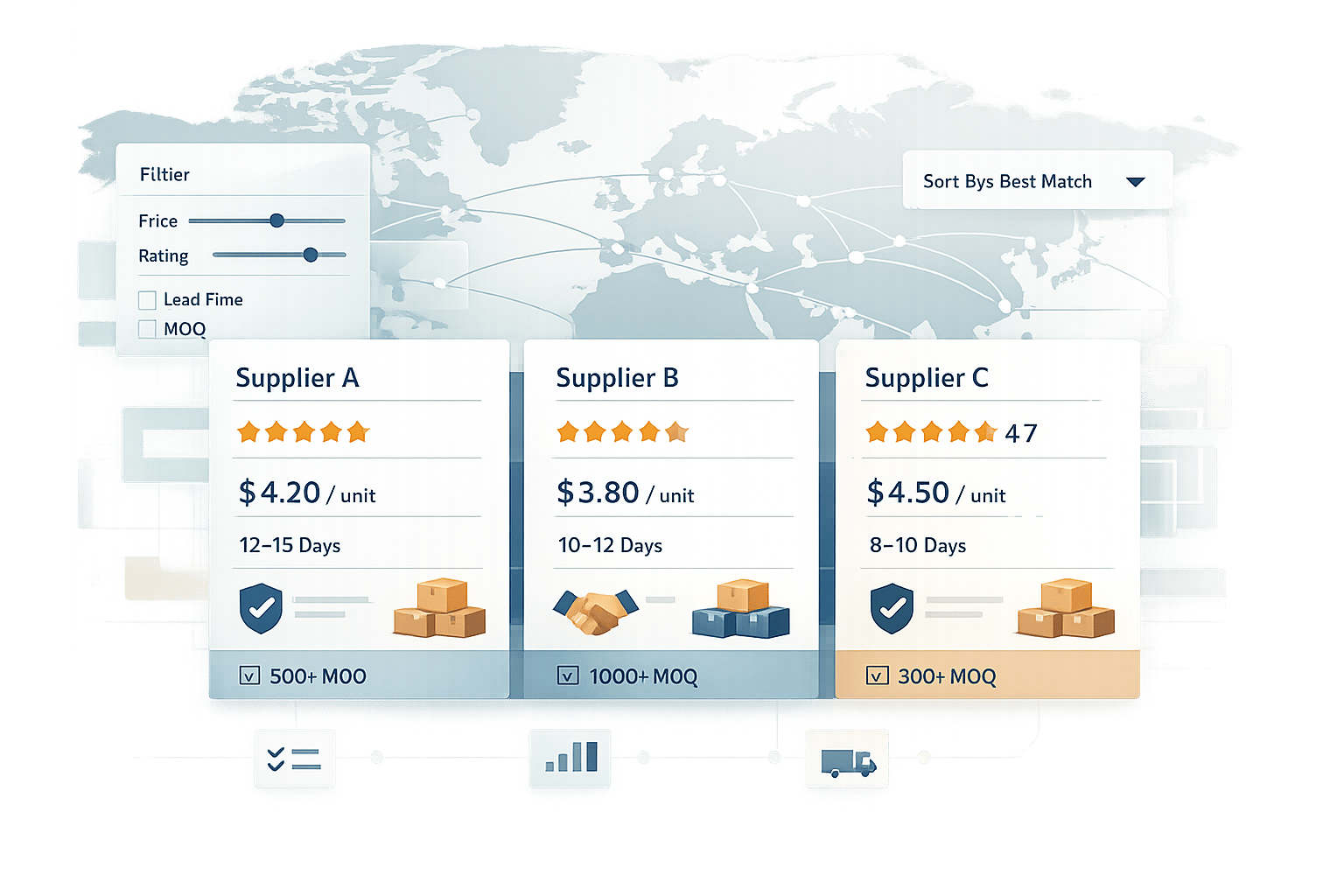

ForthSource makes supplier discovery straightforward by combining automation with transparency. Users can either search directly or paste product links from popular marketplaces. The platform then provides an instant comparison of suppliers, using various data points to help users make informed choices.

Its scoring system evaluates suppliers across multiple metrics, including pricing accuracy, data completeness, domain reputation, verified reviews, and sentiment scores. This comprehensive analysis gives sourcing managers a clear picture of each supplier's reliability and trustworthiness.

ForthSource also ensures privacy with a secure, platform-free workspace. This means businesses can research and compare suppliers without worrying about vendors tracking their activity. By keeping the process confidential, companies can evaluate options freely and without external pressure.

The results speak for themselves. Alex Chan, Supply Lead at Luma Goods, shared his experience:

"We cut sourcing time by 40% using ForthSource's scoring system. Game changer."

This level of efficiency shows how tools like ForthSource can save time while still maintaining high standards for quality and reliability.

Key Features of ForthSource

What sets ForthSource apart from traditional supplier directories is its unique combination of automated scoring and secure data management. Here’s a closer look at its standout features:

- Data-backed trust scores: These scores combine key factors like price competitiveness, domain credibility, review sentiment, and data quality into a single, easy-to-digest metric.

- Cross-platform comparison: Users can view supplier listings side by side, ranked by real-time performance and reliability.

- Sentiment signals: Available in the Pro tier, these signals analyze reviews from sources like Google Reviews and Trustpilot, as well as public web data, to provide a deeper understanding of supplier reputations.

- Domain trust metrics: These metrics help users identify trustworthy suppliers and avoid potentially unreliable ones - a particularly useful feature for businesses prioritizing long-term reliability.

Additionally, ForthSource includes workflow tools to streamline the sourcing process. Features like saved searches and search history allow teams to track shortlisted suppliers, revisit past comparisons, and share data across departments. Users can also export results and collaborate with their teams in one centralized workspace.

Pricing and Plans

ForthSource follows a freemium model, offering both free and paid options to accommodate businesses of various sizes and budgets. This approach ensures that U.S. DTC brands can access quality supplier data without an upfront financial commitment.

The Free Plan offers limited search capabilities, allowing users to view up to three enhanced suppliers per query. It includes basic scoring functionality and provides partial trust data for top suppliers, giving users a glimpse of the platform’s potential. However, advanced features like detailed sentiment analysis and full domain trust metrics are reserved for the paid tier.

ForthSource is also preparing to roll out a Paid Plan, which will unlock the full suite of features. This plan will include access to over ten enhanced suppliers per search, complete sentiment breakdowns, and the ability to save searches. While pricing details for the paid plan haven’t been disclosed yet, it’s designed to meet the needs of growing DTC brands that require more comprehensive supplier insights.

The freemium model allows businesses to explore ForthSource’s core features before committing to a subscription, making it an attractive option for both startups and established brands. This flexibility is particularly valuable for DTC brands, which often start with limited resources but need advanced tools as they grow.

sbb-itb-633367f

How to Use Supplier Rating Systems Effectively

To make the most of supplier rating systems, it’s essential to establish clear criteria, understand the context behind scores, and apply insights to meet specific business goals. For sourcing managers and DTC brands, this means tailoring the system to align with their unique needs and challenges.

Setting Up Rating Criteria

The backbone of any successful supplier evaluation lies in defining measurable criteria that directly tie into your business objectives. Companies with effective supplier performance management systems often see supply costs drop by 3-8%, all while improving quality and delivery performance.

Rather than trying to measure everything, zero in on the 4-8 most critical factors. For example, DTC brands might prioritize metrics like production capacity, risk management, and environmental impact, in addition to the usual cost and quality considerations.

To make evaluations fair and actionable, assign weights to each criterion based on its importance. Weighted scores ensure a balanced view, combining pricing with performance. For instance, a DTC brand launching a new product line might weight quality at 40%, delivery time at 30%, cost at 20%, and sustainability at 10%.

| Criteria | Weight (%) | Supplier A | Supplier B | Supplier C |

|---|---|---|---|---|

| Cost | 20 | 4 | 4 | 2 |

| Quality | 40 | 3 | 3 | 5 |

| Delivery Time | 30 | 3 | 3 | 2 |

| Sustainability | 10 | 3 | 3 | 4 |

| Total Score | 3.1 | 3.1 | 3.3 |

Clarity is key. Define how each criterion will be measured to avoid misinterpretation. For example, delivery performance might be tracked as the percentage of on-time shipments, while quality could be assessed through defect rates or customer return percentages.

Once your criteria are in place, the next step is to make sense of the data these systems generate.

Reading Scores and Sentiment Data

Numbers alone don’t tell the whole story. Supplier rating systems provide numerical scores, but interpreting these alongside sentiment data can uncover trends and potential red flags.

While most systems track metrics like quality, delivery, cost, and compliance, their true value lies in understanding what the numbers reveal. For instance, a supplier with a slightly lower score but consistent improvement might be a better long-term partner than one with high scores but a downward trend.

Sentiment analysis adds another dimension by analyzing reviews from platforms like Google Reviews and Trustpilot. These insights can highlight issues that raw numbers might overlook. Additionally, domain trust metrics can help identify legitimate suppliers versus unreliable ones.

"Supplier metrics generate data to improve supply chain efficiency and reduce costs." - Adar Hay, Co-Founder and CEO of Jiga

Supplier scorecards can also help identify challenges on both sides of the partnership. By addressing not only the supplier’s shortcomings but also how your company might be contributing to any issues, you can foster stronger, more collaborative relationships.

Once you’ve analyzed the data, it’s time to apply these insights to select the best suppliers for your specific needs.

Supplier Selection for U.S. Businesses

For U.S.-based DTC brands, sourcing globally comes with its own set of challenges, including compliance, shipping delays, and quality control. 72% of SMBs report unpredictable delivery times, with lead time variability affecting 67% of businesses sourcing from China compared to 56% for domestic suppliers.

To navigate these hurdles, focus on suppliers that meet U.S. regulatory standards, offer reliable shipping, and communicate effectively during U.S. business hours. Key factors to evaluate include:

- Compliance with U.S. product safety standards.

- Proximity to major shipping hubs and familiarity with customs procedures.

- Strong partnerships with dependable freight forwarders.

The 2007 Mattel recall of 18 million toys due to lead-contaminated paint serves as a cautionary tale. This incident cost the company $30 million in direct expenses and caused a significant drop in stock value. In response, Mattel overhauled supplier relationships, implemented stricter inspections, and enhanced auditing processes.

Time zone differences and language barriers also play a role in supplier relationships. Ensure your rating system accounts for a supplier’s responsiveness during U.S. business hours and their ability to communicate clearly in English, which is critical for resolving issues quickly.

Finally, schedule regular review meetings to discuss performance trends and identify improvement opportunities. This ongoing dialogue not only strengthens supplier relationships but also ensures continuous alignment with your business goals.

Key Takeaways for Sourcing Managers and DTC Brands

Supplier rating systems have become indispensable for sourcing managers and DTC brands, offering a way to cut supply costs by 3–8% while improving quality and delivery performance. These platforms provide much-needed transparency, enabling better decision-making and risk management.

With modern tools, sourcing managers gain access to detailed performance metrics, sentiment analysis, and risk indicators. This means decisions are no longer based on intuition or limited references but are instead grounded in data. A key benefit here is risk mitigation. Spotting early warning signs - like financial instability, compliance issues, or operational challenges - allows businesses to adapt quickly and maintain stability. This is critical when you consider that 21.05% of companies with a SER rating of 9 are likely to go out of business, become inactive, or file for bankruptcy.

Another advantage is standardized benchmarking, which ensures fair comparisons across suppliers regardless of region or category. This eliminates bias and supports competitive, sustainable procurement practices.

For DTC brands, supplier rating systems address global sourcing challenges in real time. From meeting U.S. product safety standards to overcoming time zone differences and communication barriers, these systems streamline operations. For example, evaluating supplier responsiveness during U.S. business hours and their English communication skills can be vital for smooth collaboration.

Continuous performance improvement is another major benefit. Research indicates that using standardized metrics to measure supplier performance leads to an average improvement of 26.6%. This progress comes from setting clear expectations, delivering regular feedback, and encouraging collaboration between buyers and suppliers.

Sustainability further enhances supplier relationships. With 91% of companies now factoring sustainability ratings into purchasing decisions, it’s clear that both consumer demand and regulatory pressures are reshaping procurement strategies. By prioritizing sustainability, businesses not only meet these expectations but also strengthen their partnerships.

ForthSource exemplifies this data-driven approach by offering direct, sentiment-enriched supplier data. Its composite scoring system, which evaluates pricing, credibility, and public sentiment, equips sourcing managers with actionable insights to make smarter decisions.

Ultimately, success lies in focusing on the 4–8 most critical metrics for your business, whether it’s production capacity, risk management, environmental impact, or cost efficiency. Defining and consistently applying these criteria across your supplier base ensures a streamlined and effective sourcing strategy.

Supplier rating systems are more than just tools - they’re strategic assets that strengthen partnerships, reduce risks, and enhance efficiency in today’s complex global market. For sourcing managers and DTC brands, investing in these systems is no longer optional - it’s essential.

FAQs

How can supplier rating systems help lower supply chain costs and improve delivery efficiency?

Supplier rating systems are essential for streamlining supply chain operations. By pinpointing dependable and top-performing suppliers, these systems help tackle challenges like delays, defects, and inconsistent quality. The result? Potential cost savings that can range from 3% to 8% of your supply chain expenses.

Beyond cost savings, these systems improve delivery efficiency by building stronger relationships with suppliers and ensuring they meet performance expectations. This leads to smoother workflows, fewer disruptions, and greater trust across the sourcing process - all of which can positively impact your bottom line.

What are the advantages of using AI and predictive analytics in supplier rating systems?

AI and predictive analytics are transforming supplier rating systems by enhancing the precision and depth of evaluations. These technologies enable businesses to spot potential risks earlier, improve decision-making, and anticipate supplier performance trends. The result? Smarter and more informed sourcing decisions.

With AI-powered insights, companies can minimize sourcing risks, simplify the supplier selection process, and establish more dependable partnerships. This leads to greater trust and efficiency when managing global supply chains.

Why should U.S. businesses prioritize compliance and currency management features in supplier rating systems?

For businesses in the U.S., staying compliant isn't just about avoiding hefty fines - it's also about meeting regulatory standards and earning the trust of both partners and customers. A supplier rating system equipped with strong compliance tools can make this process much easier by pinpointing suppliers who adhere to legal and industry-specific requirements.

Equally crucial are tools for managing currency in international transactions. These features help minimize errors, ensure precise exchange rates, and deliver transparent financial reporting. This level of accuracy is essential for mitigating risks and maintaining reliable financial records in global sourcing.